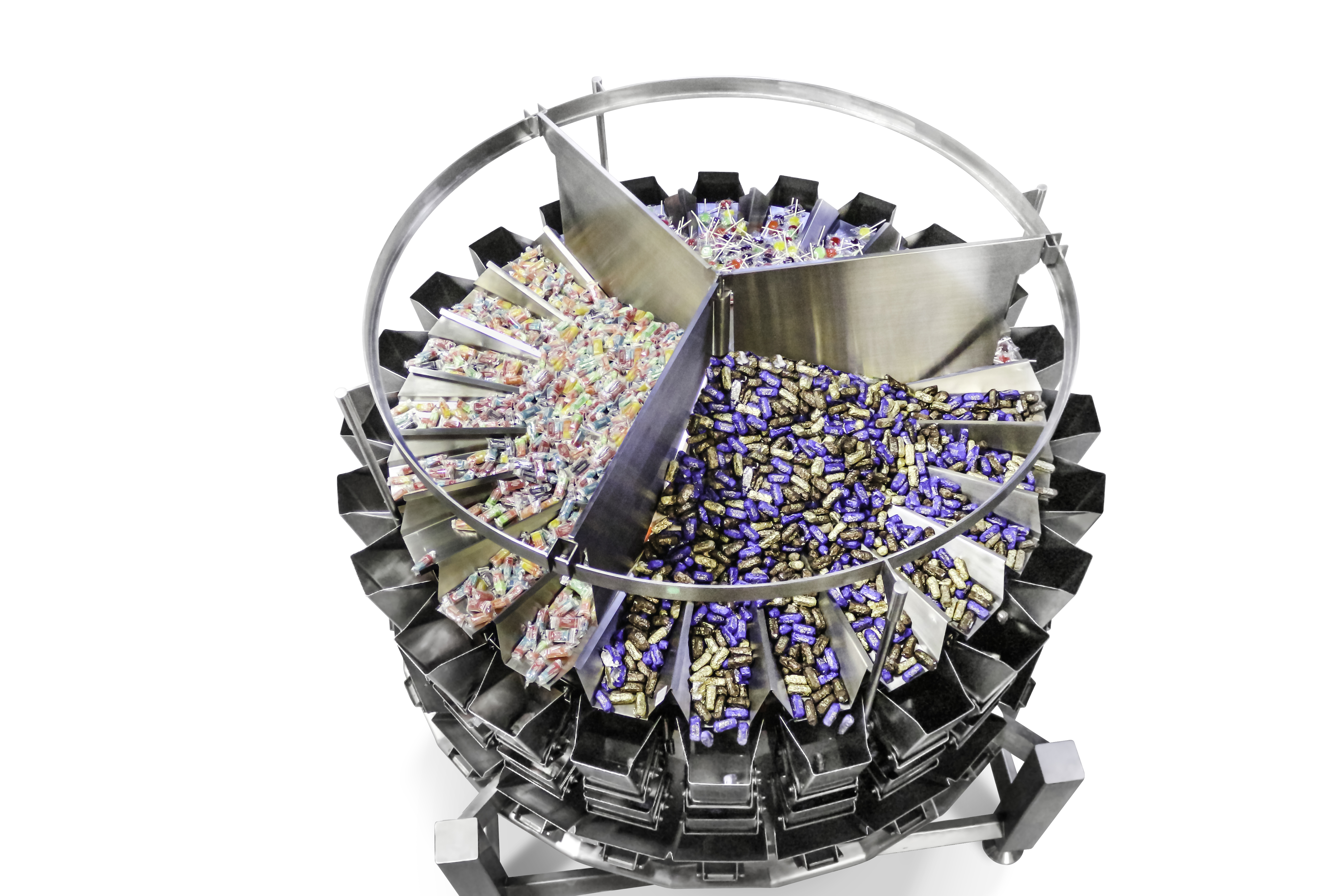

WeighPack Systems Multi-head weighing machines are an essential tool for food manufacturers, providing a fast and accurate way to weigh and fill food products. These machines use multiple weigh heads to measure and dispense the correct amount of product into packaging, ensuring consistent portion sizes and reducing waste. Here are some of the key advantages of using a multihead weighing machine for food products:

Accuracy: PrimoCombi Multi-head weighing machines use advanced technology to accurately measure and dispense food products, ensuring consistent portion sizes and reducing waste. This is particularly important for products sold by weight, where even small discrepancies can have a significant impact on profitability.

Speed: PrimoCombi Multi-head weighing machines can weigh and fill multiple packages simultaneously, significantly increasing production speed and efficiency. This allows food manufacturers to keep up with demand and reduce downtime.

Versatility: PrimoCombi Multi-head weighing machines can handle a wide range of food products, from dry goods like grains and cereals to fresh produce and meats. They can also be configured to handle different package sizes and shapes, making them a versatile tool for food manufacturers.

Reduced Labor Costs: PrimoCombi Multi-head weighing machines automate the weighing and filling process, reducing the need for manual labor and increasing efficiency. This can help food manufacturers save on labor costs and improve their bottom line.

In conclusion, multi-head weighing machines offer a range of benefits for food manufacturers, including increased accuracy, speed, versatility, and reduced labor costs. By investing in this technology, food manufacturers can improve their production processes and increase their profitability.