The stand up bag machine, or also known as ‘SUP, SURP or DOY Packs’ offers advantages to the manufacturer and the consumer as compared to other conventional packaging choices.

STAND UP BAG MACHINE ADVANTAGES

When it comes to its physical appearance, our stand up bag machine produces a stand up bag with a high gloss finish leaving a pleasant impression on your customers. Another benefit is its space-saving feature thanks to its bottom gusset design. It will save you some shelf space. For example, when you put it away in a garage, closet, kitchen cupboard or refrigerator. Lastly, stand up pouches are very convenient to use since it is equipped with a re-closeable feature in the form of zipper closures.

Automatic Stand Up Bagging Machine Solutions

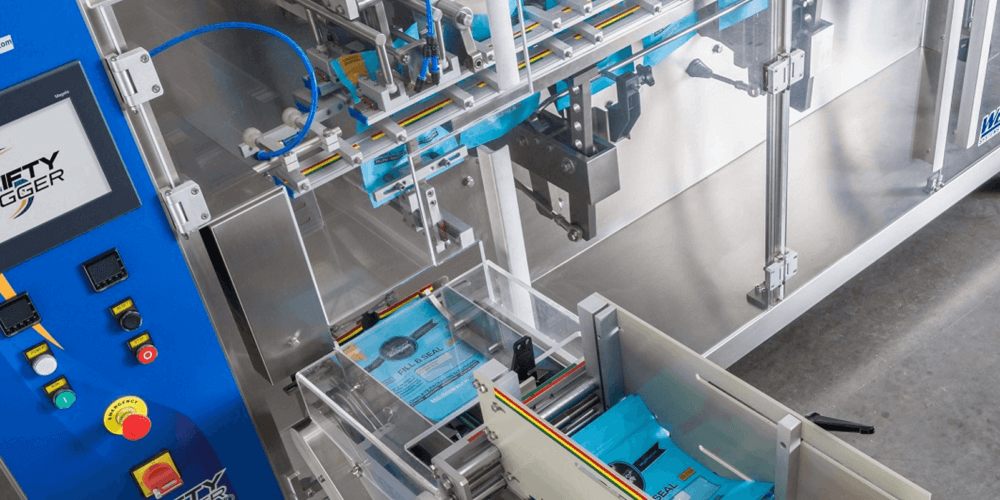

As a leader in automatic stand up bagging machine solutions for pre-made and wicket bags, we have engineered a number of machines. Therefore, all designed to automatically open, fill and seal a wide range of pouches or bags. These include stand-up (SUP or SURP), laminated or polyethylene materials, and pillow pouches. Additionally, 4 sided seal, 3 side seal and quad pouches with zippers (or carry handle). We have three bagging machines for pre-made pouches, the Swifty Junior, Swifty 1200 and Swifty 3600.

Swifty Junior for mid-level production rates up to 800 bags per hour

Swifty 1200 for larger bag size requirements up to 1,800 bags per hour

Swifty 3600 for speeds of up to 2,500 bags per hour

The Swifty Junior has standard features such as automatic bag magazine, stainless steel frame. In addition to, an Omron PLC and touch screen. Whereas, the Swifty 1200 and Swifty 3600 have common features including an easy-load bag feeder, photosensor for bag opening detection, and PLC touch screen. Our Swifty Bagger family of automatic bag filling machines is engineered for performance, serviceability, cleanability, and ease of use.

Pre-made wicket stand up bag machine

As for the pre-made wicket bags, we have another three stand up bag machine products namely, the VS Bagger, Bingo Bagger and Zippy Bagger. Our VS Bagger is perfect for applications that do not require sealing. It can be integrated with an existing sealer or locking device. Thus, it operates by automatically positioning a pre-made wicket pouch under the fill zone. It transfers to the next station of the packaging process. Second is the Bingo Bagger featuring the intermittent sealing jaws and its available upgrade option for vacuum packaging. It is known to improve food safety by eliminating human interaction in the sealing process. Finally, we have the Zippy Bagger that is commonly used for higher speed applications with rates up to 2,000 bags per hour.