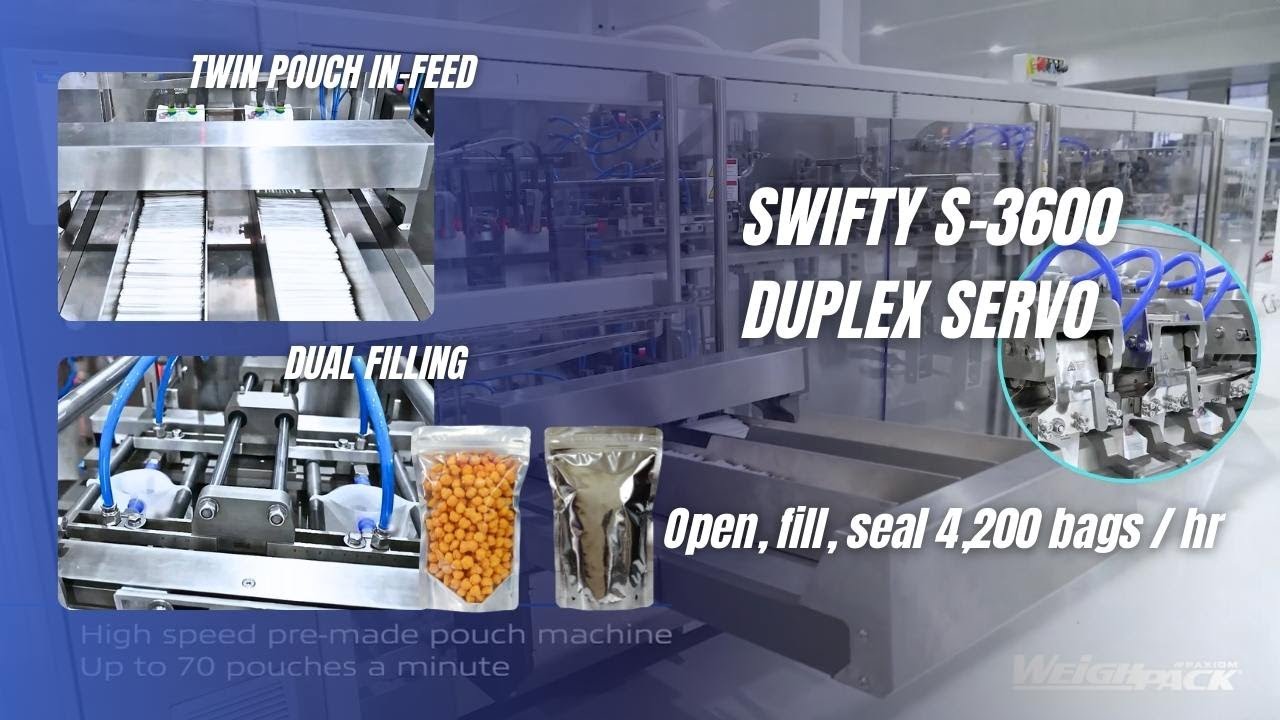

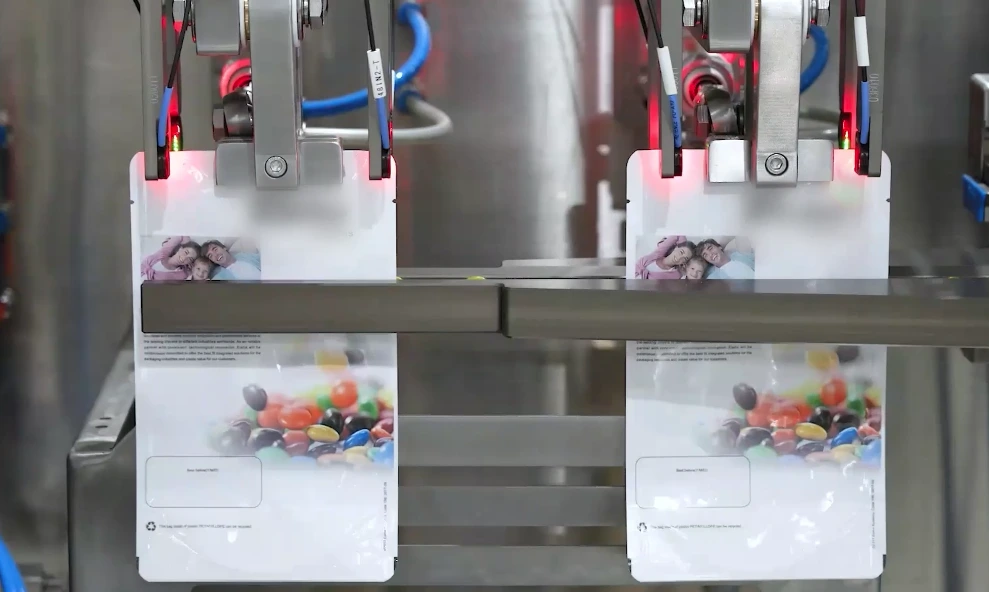

Swifty Bagger S-3600

HIGH SPEED POUCH FILLING MACHINE WITH DUPLEX SERVO

The Swifty Bagger S-3600 revolutionizes high-speed pouch bagging, prioritizing productivity, versatility, and user ease. It swiftly processes up to 70 pouches per minute (4,200 per hour), expertly handling various products with precision. Equipped with dual infeed conveyors and fill stations, it ensures seamless, high-volume production.

Inheriting the legacy of trusted Swifty Bagger technology, the S-3600 features a streamlined, operator-friendly design. Its straightforward layout offers clear visibility of the entire bagging process, minimizing labor needs and simplifying maintenance.

Seamlessly integrating with printers, the Swifty Bagger family empowers businesses to enhance product value with customized branding, QR codes, and expiration dates, boosting efficiency and market appeal.

Videos

Features

- High-Speed Performance: Opens, fills, and seals up to 70 pouches per minute.

- Dual Fill Stations: Versatile handling of liquids, solids, and powders.

- Straight-Line Design: Simplifies operation with clear visibility of all processes.

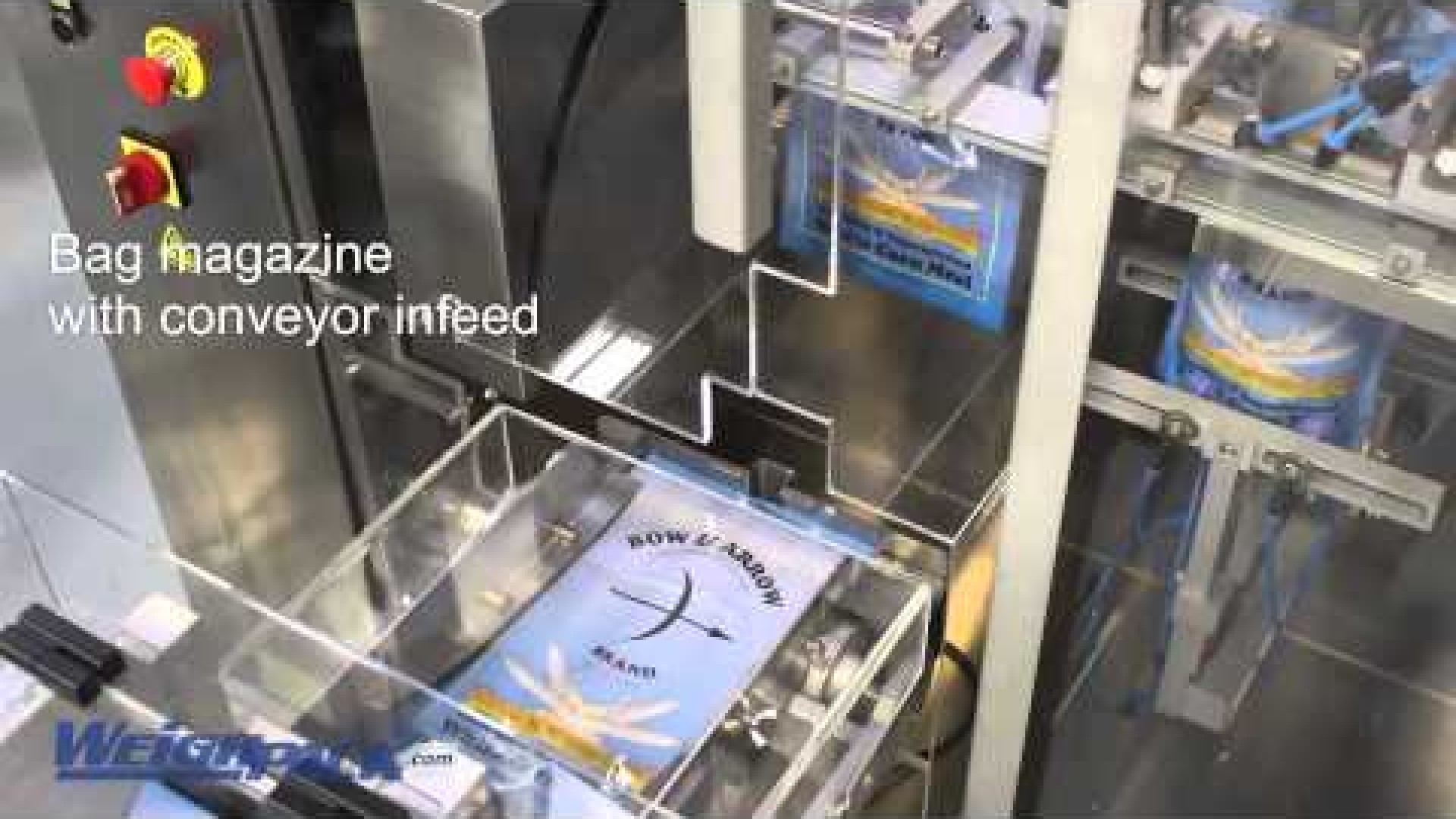

- Bag Magazine: Ensures consistent pouch alignment for precise performance.

- Automatic Zipper Opener: Streamlines pouch preparation.

- Bag Shaker: Levels products during filling for a polished finish.

- Integrated Exit Conveyor: Improves handling efficiency.

- Printer Integration: Compatible with various printers for on-pouch coding and branding.

*Rates subject to package style, type and size

Our Swifty Bagger S-3600 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- High-Speed Performance: Opens, fills, and seals up to 70 pouches per minute.

- Dual Fill Stations: Versatile handling of liquids, solids, and powders.

- Straight-Line Design: Simplifies operation with clear visibility of all processes.

- Bag Magazine: Ensures consistent pouch alignment for precise performance.

- Automatic Zipper Opener: Streamlines pouch preparation.

- Bag Shaker: Levels products during filling for a polished finish.

- Integrated Exit Conveyor: Improves handling efficiency.

- Printer Integration: Compatible with various printers for on-pouch coding and branding.

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger S-3600 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

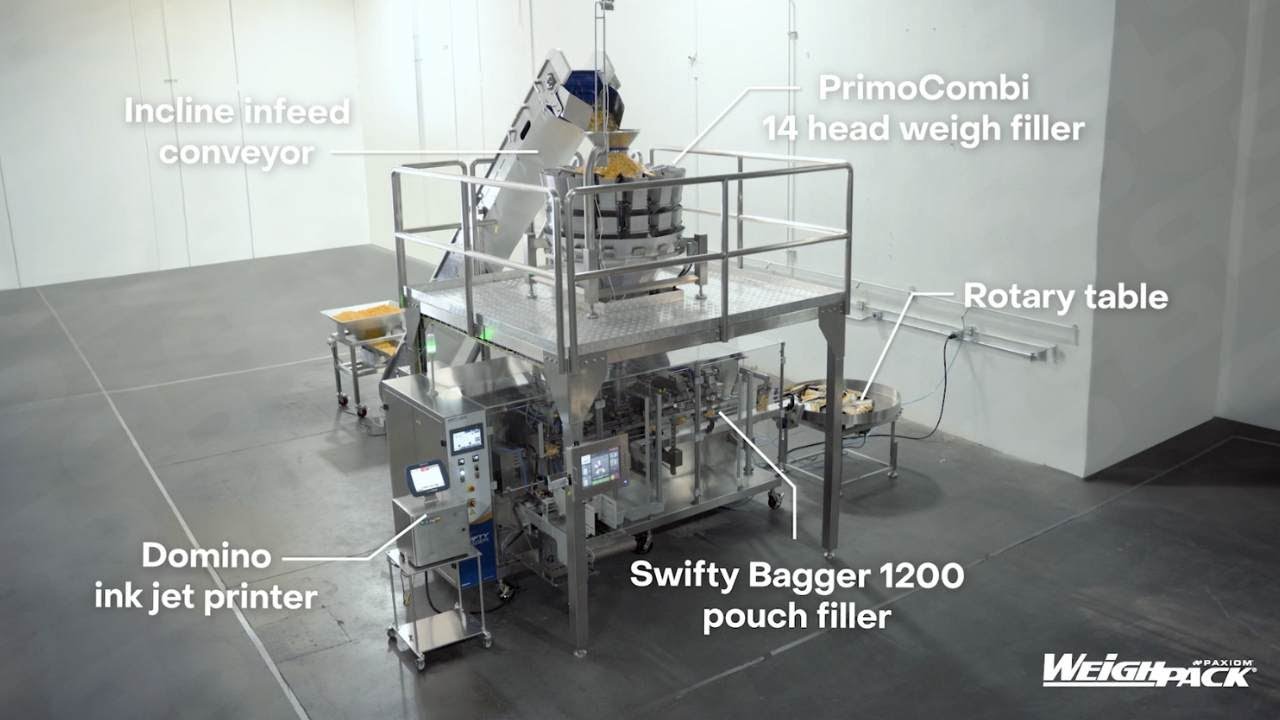

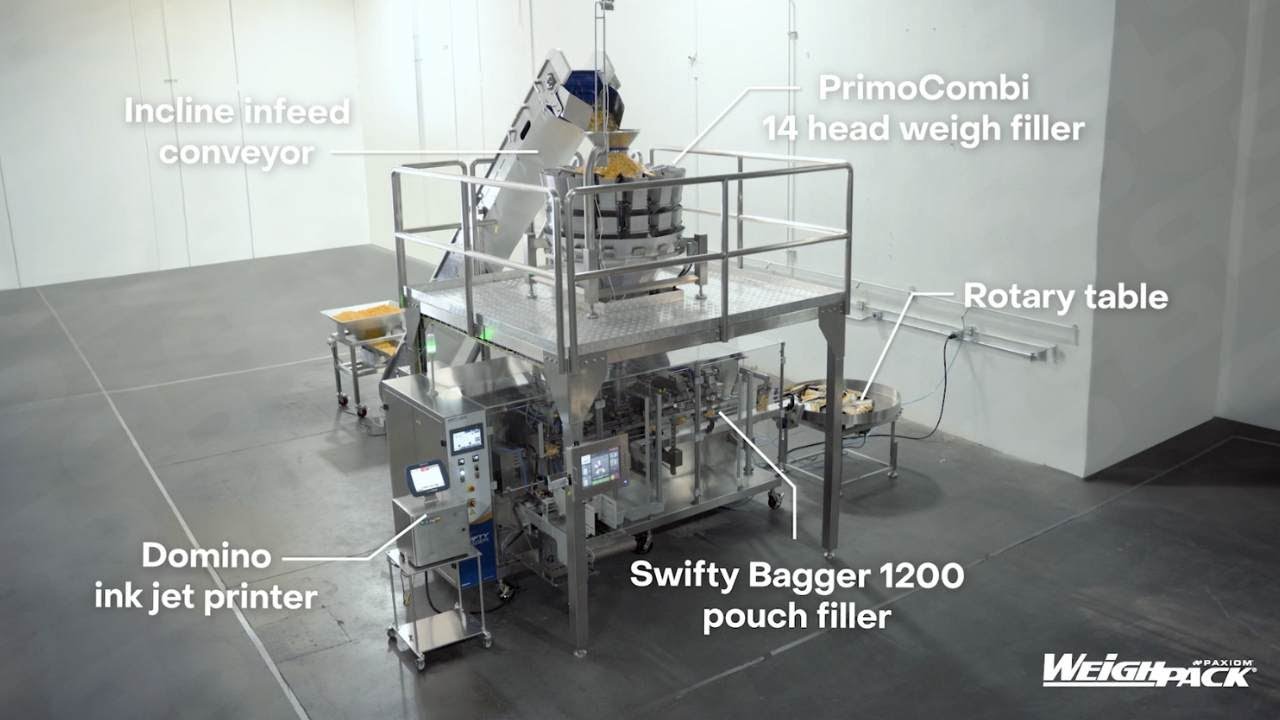

Swifty Bagger 3600 & 1200

DURABLE POUCH FILLING

Swifty Bagger 3600 and 1200 models are engineered for medium to high production rates.

Both cam driven automatic bagging machines are robust in design and built to last the vigor’s of today’s production needs.

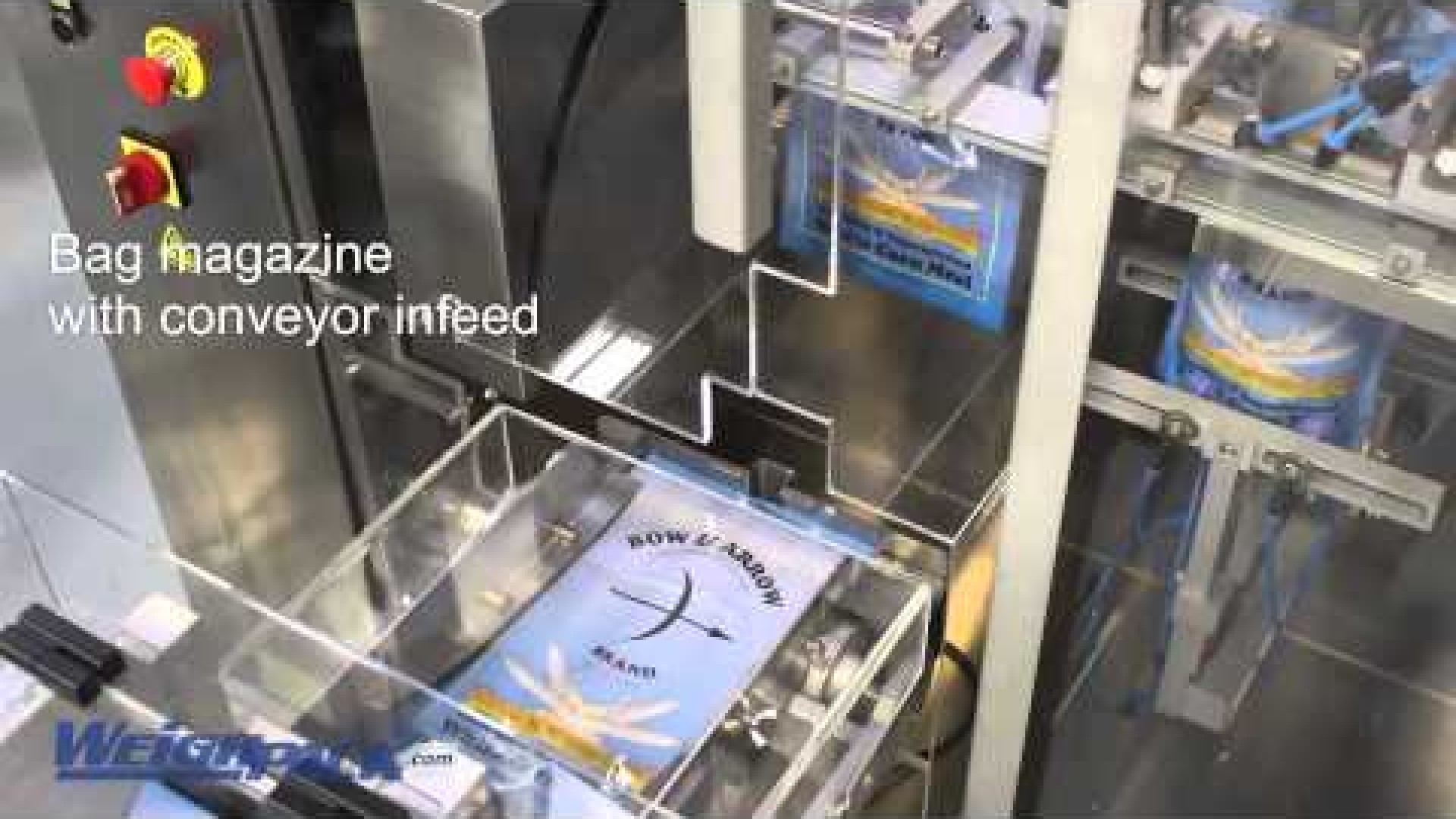

The Swifty Bagger includes a very accessible bag magazine for convenient pouch loading, automatic zipper opening device, bag shaker at the fill station for product leveling and integrated exit conveyor.

Fill the following pouches with the Swifty Bagger: Stand up pouch (SUP, SURP, DOY), pillow, gusseted, quad and carry handle.

Videos

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

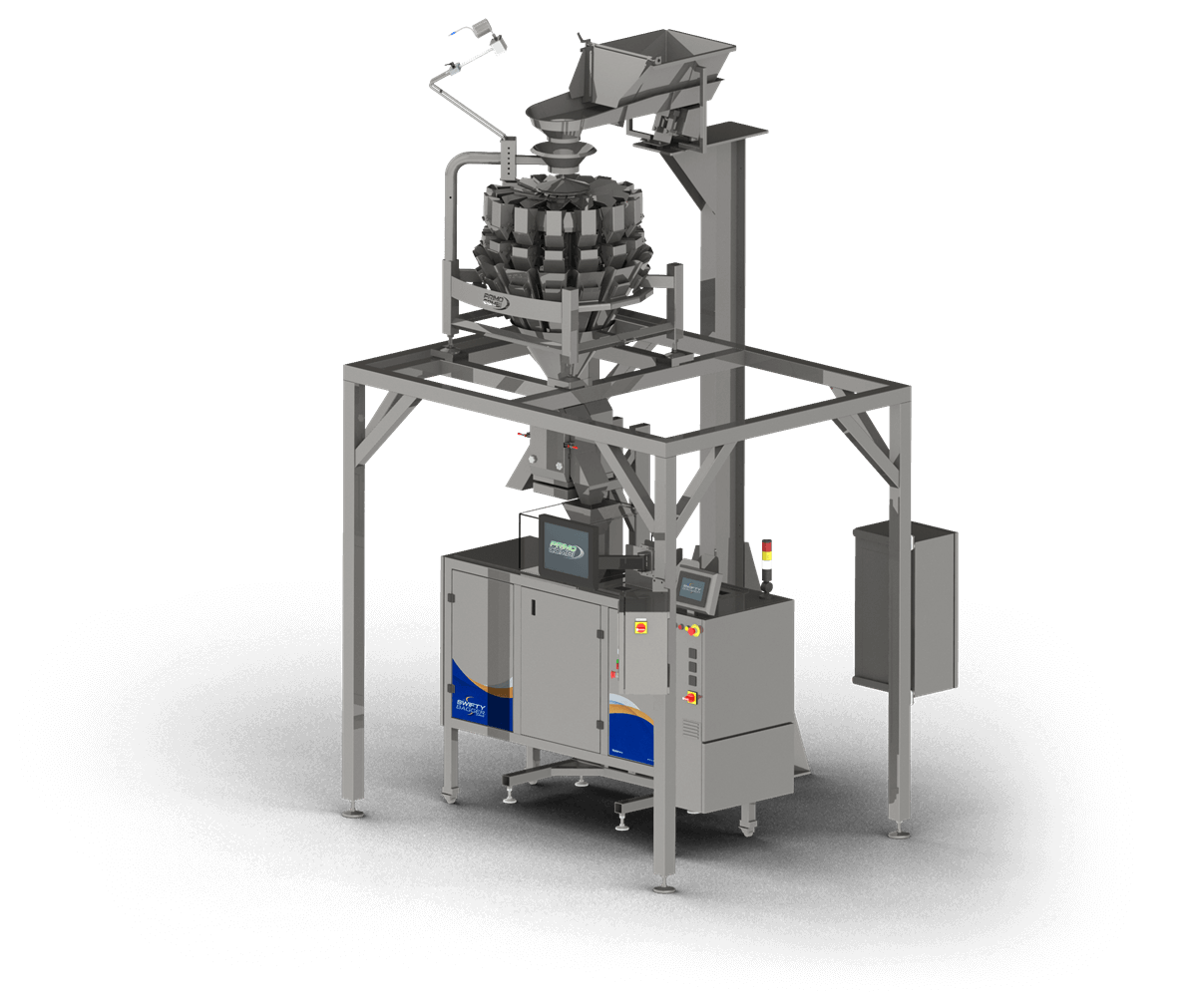

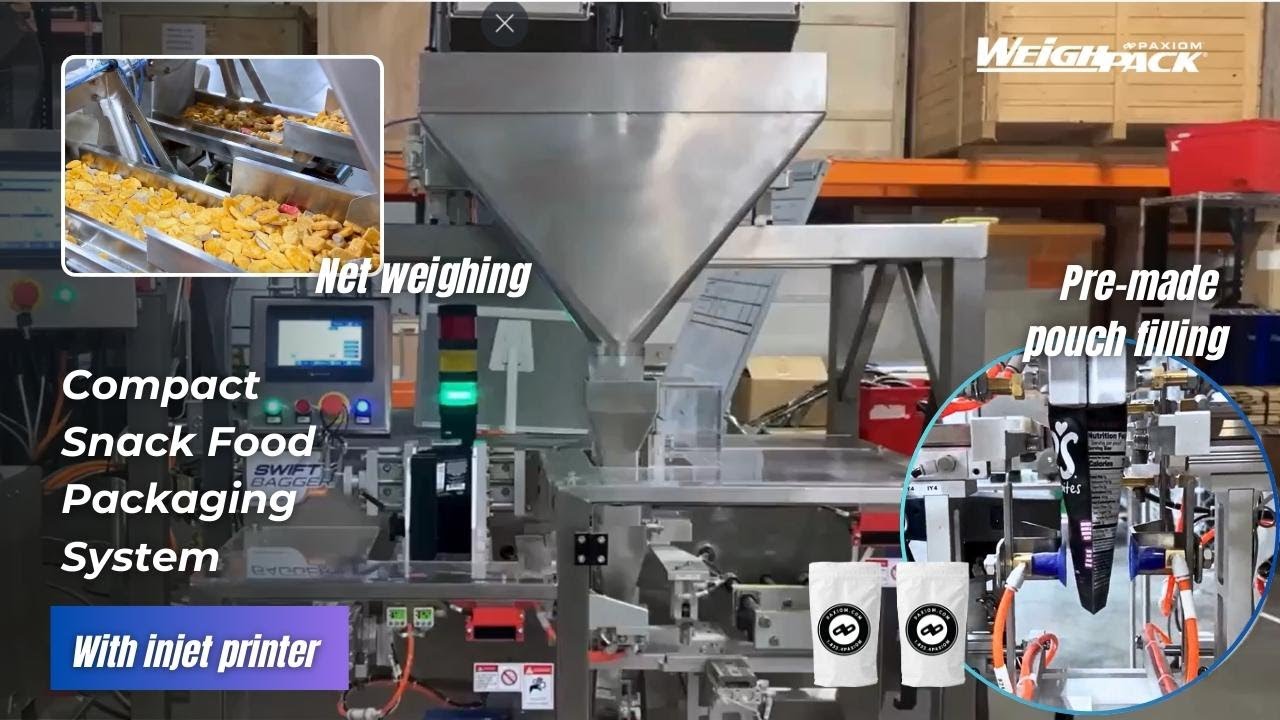

SWIFTY BAGGER MINI

COMPACT POUCH FILLING

The Swifty Bagger Mini stand-up pouch filling machine is perfect for compact bag sizes. The Mini automatically opens, fills and seals a variety of premade stand-up pouches. With our smallest footprint, this machine occupies only 10 square feet of floor space and easily rolls to fit within your existing production environment.

The Mini is constructed with stainless steel and is easy to use, easy to service and easy to maintain. It features an easy-to-adjust bag magazine for convenient feeding that ensures premade pouches enter the machine perfectly square, resulting in consistent output and seals.

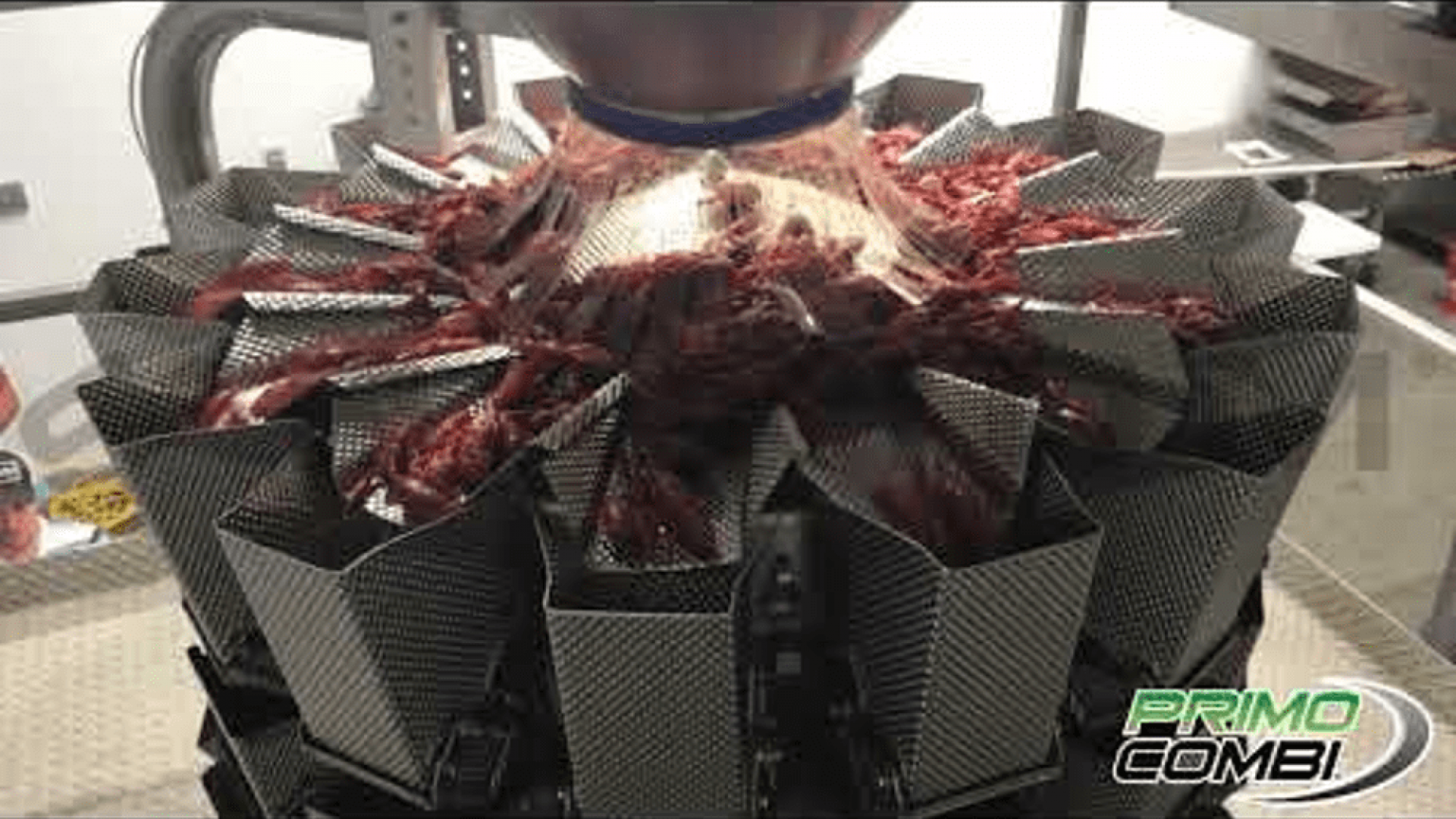

The Swifty Bagger Mini easily integrates with any auxiliary filling machines including our PrimoCombi multi-head weigher, PrimoLinear net weigher and Star Auger for powder filling.

Videos

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

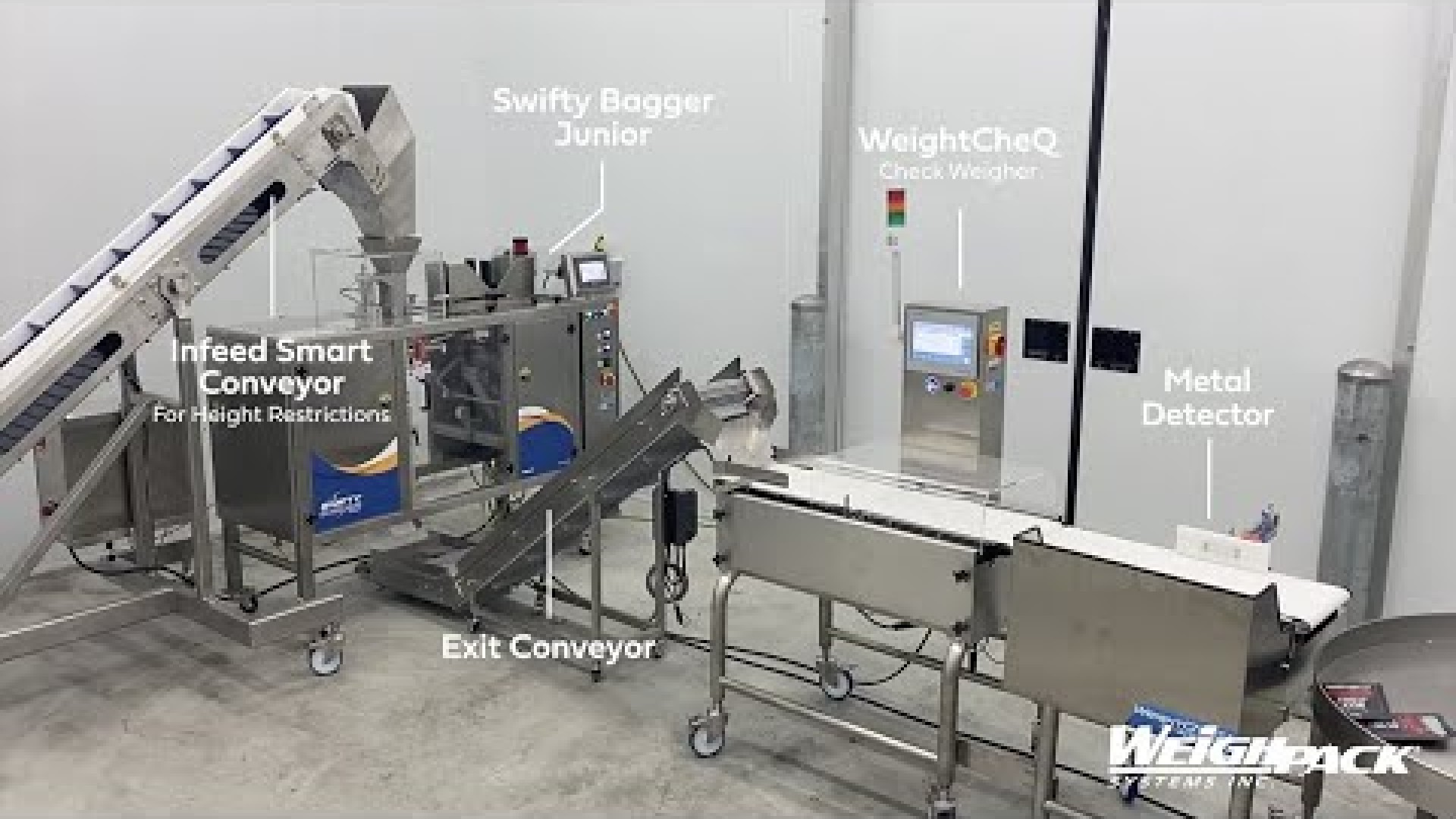

SWIFTY BAGGER JUNIOR

ONE PROCESS POUCH FILLING

The Swifty Junior pouch filling machine automatically opens, fills and seals premade stand-up pouches (SUP, SURP, DOY) in one process, making it easy to use and easy to integrate with multi-head weighing, net weighing and auger filling machines.

The Swifty Junior is extremely compact requiring only ten square feet of floor space and is perfect for small to medium production rates of up to 900 bags per hour.

Videos

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Jr is suited for all industries as your go to one process pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Jr is suited for all industries as your go to one process pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

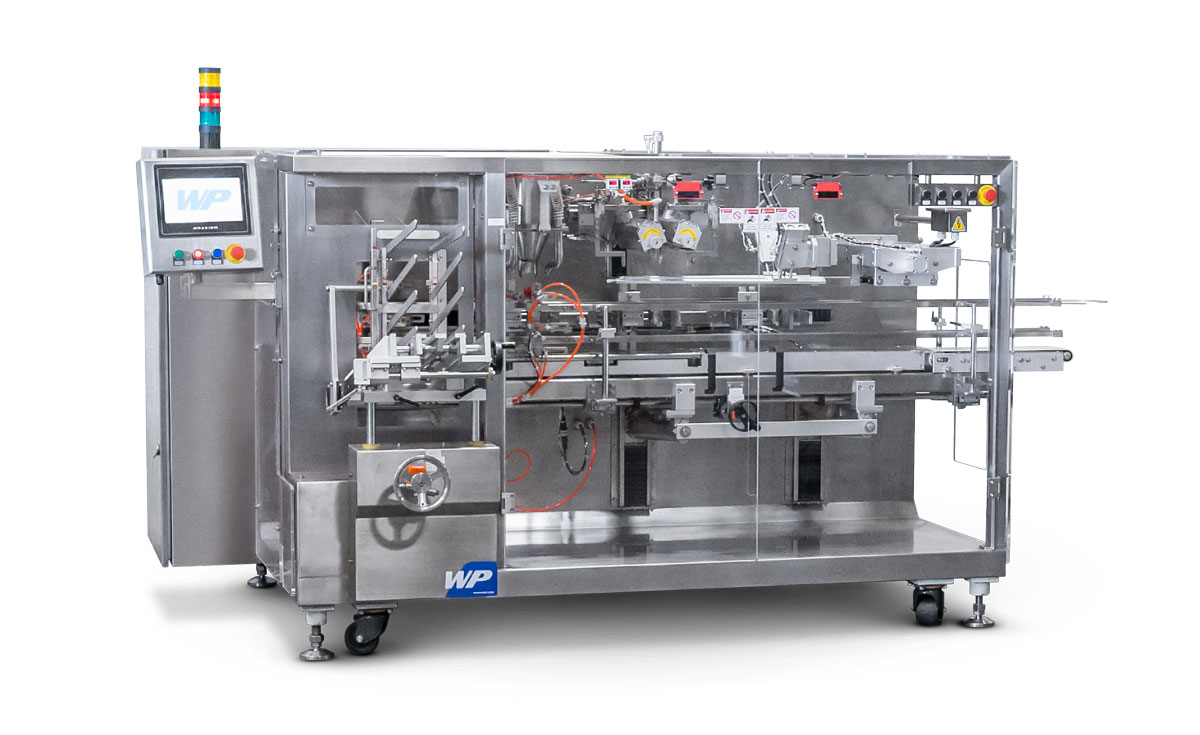

SWIFTY BAGGER SIDE LOAD

HORIZONTAL POUCH FILLING

Our unique Swifty Bagger Side Load automatic bagging machine is engineered to load and fill pre-made pouches horizontally.

Loading product horizontally creates a distinct appearance within the pouch that works well for marketing pre-packaged snack foods and supplements as well as pet chews and is perfect for products that need to be oriented in a specific direction such as medical devices or printed materials.

Constructed with stainless steel, this machine features a quick bag loading station with vacuum mechanism, a color touch screen and a no bag-no fill sensor. The straight-flow design allows the operator to see the entire filling process from the front side of the machine.

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

SWIFTY BAGGER BOX GUSSET

FOR SIDE GUESSET BAGS

Automatically fill side gusset bags with block bottom, with or without a pocket zipper with our Swifty Bagger Box Gusset.

Designed to automatically open, fill, tuck and seal side gusset bags, this unique machine features an easily accessible bag magazine, automatic zipper opener, integrated bag shaker and exit conveyor.

Perfect for packaging coffee and other powder or granule products when paired with our auger powder filler. Match it with our multi-head weigher or linear net weigher and the Box Gusset will also efficiently bag other products such as candy, nuts, baked and dry goods, jerky or even hardware and textiles.

Ask about designing a fully automated system to include our WeightCheQ check weigher and other downstream solutions such as case packing and palletizing.

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

Swifty Bagger S-3600

HIGH SPEED POUCH FILLING MACHINE WITH DUPLEX SERVO

Videos

The Swifty Bagger S-3600 revolutionizes high-speed pouch bagging, prioritizing productivity, versatility, and user ease. It swiftly processes up to 70 pouches per minute (4,200 per hour), expertly handling various products with precision. Equipped with dual infeed conveyors and fill stations, it ensures seamless, high-volume production.

Inheriting the legacy of trusted Swifty Bagger technology, the S-3600 features a streamlined, operator-friendly design. Its straightforward layout offers clear visibility of the entire bagging process, minimizing labor needs and simplifying maintenance.

Seamlessly integrating with printers, the Swifty Bagger family empowers businesses to enhance product value with customized branding, QR codes, and expiration dates, boosting efficiency and market appeal.

Features

- High-Speed Performance: Opens, fills, and seals up to 70 pouches per minute.

- Dual Fill Stations: Versatile handling of liquids, solids, and powders.

- Straight-Line Design: Simplifies operation with clear visibility of all processes.

- Bag Magazine: Ensures consistent pouch alignment for precise performance.

- Automatic Zipper Opener: Streamlines pouch preparation.

- Bag Shaker: Levels products during filling for a polished finish.

- Integrated Exit Conveyor: Improves handling efficiency.

- Printer Integration: Compatible with various printers for on-pouch coding and branding.

*Rates subject to package style, type and size

Our Swifty Bagger S-3600 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- High-Speed Performance: Opens, fills, and seals up to 70 pouches per minute.

- Dual Fill Stations: Versatile handling of liquids, solids, and powders.

- Straight-Line Design: Simplifies operation with clear visibility of all processes.

- Bag Magazine: Ensures consistent pouch alignment for precise performance.

- Automatic Zipper Opener: Streamlines pouch preparation.

- Bag Shaker: Levels products during filling for a polished finish.

- Integrated Exit Conveyor: Improves handling efficiency.

- Printer Integration: Compatible with various printers for on-pouch coding and branding.

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger S-3600 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

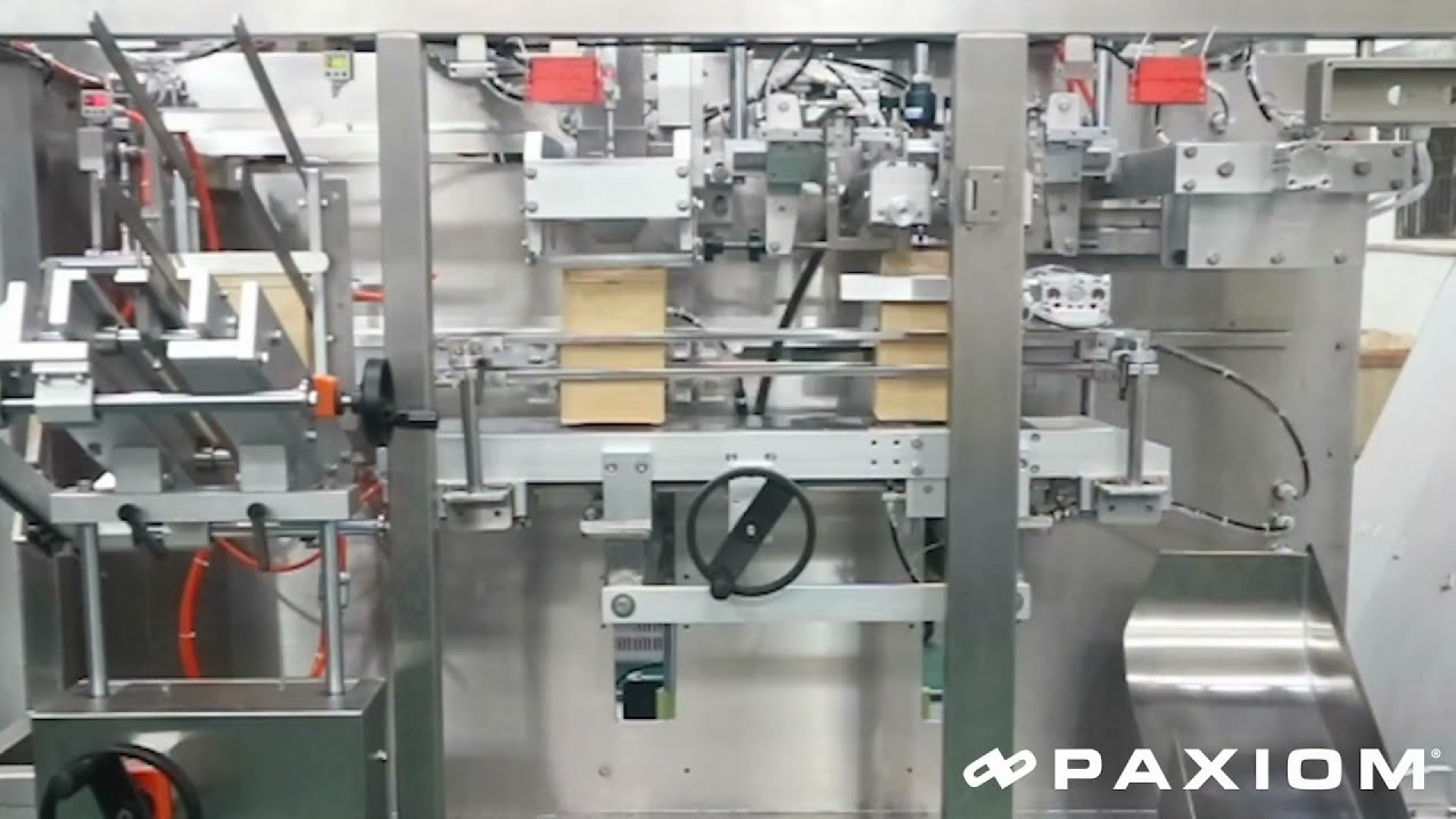

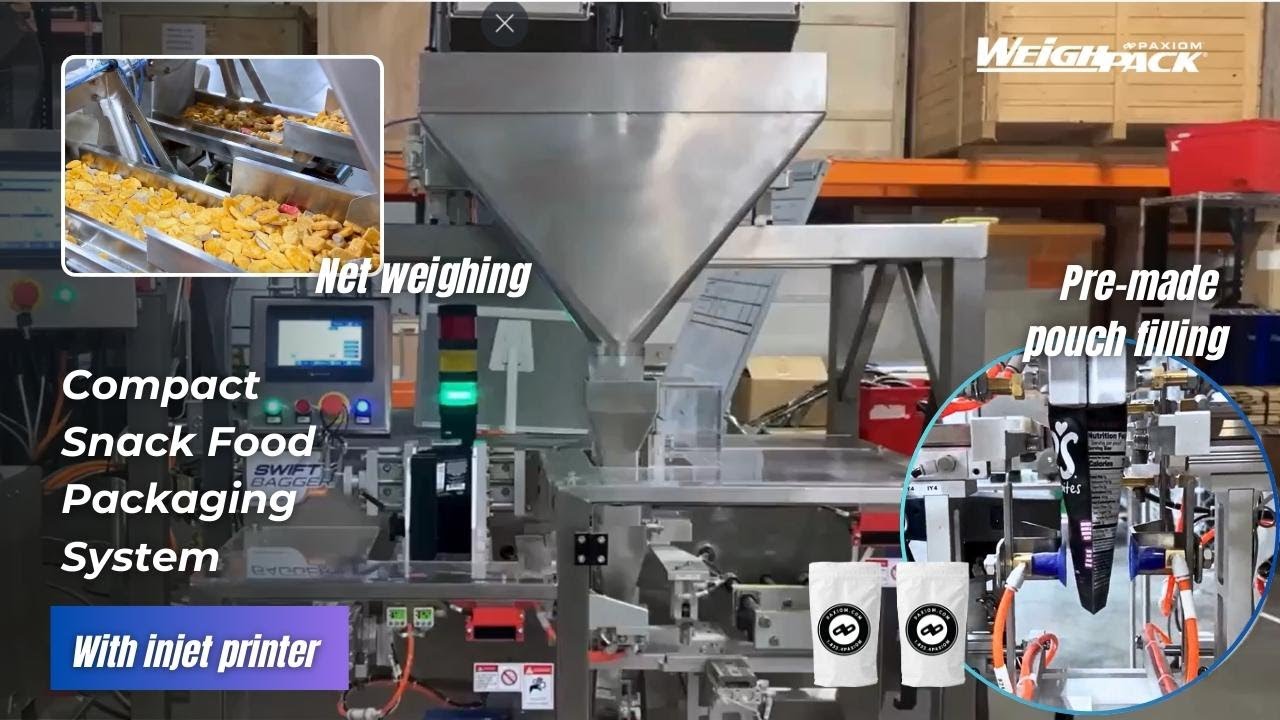

Swifty Bagger 3600 & 1200

DURABLE POUCH FILLING

Videos

Swifty Bagger 3600 and 1200 models are engineered for medium to high production rates.

Both cam driven automatic bagging machines are robust in design and built to last the vigor’s of today’s production needs.

The Swifty Bagger includes a very accessible bag magazine for convenient pouch loading, automatic zipper opening device, bag shaker at the fill station for product leveling and integrated exit conveyor.

Fill the following pouches with the Swifty Bagger: Stand up pouch (SUP, SURP, DOY), pillow, gusseted, quad and carry handle.

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

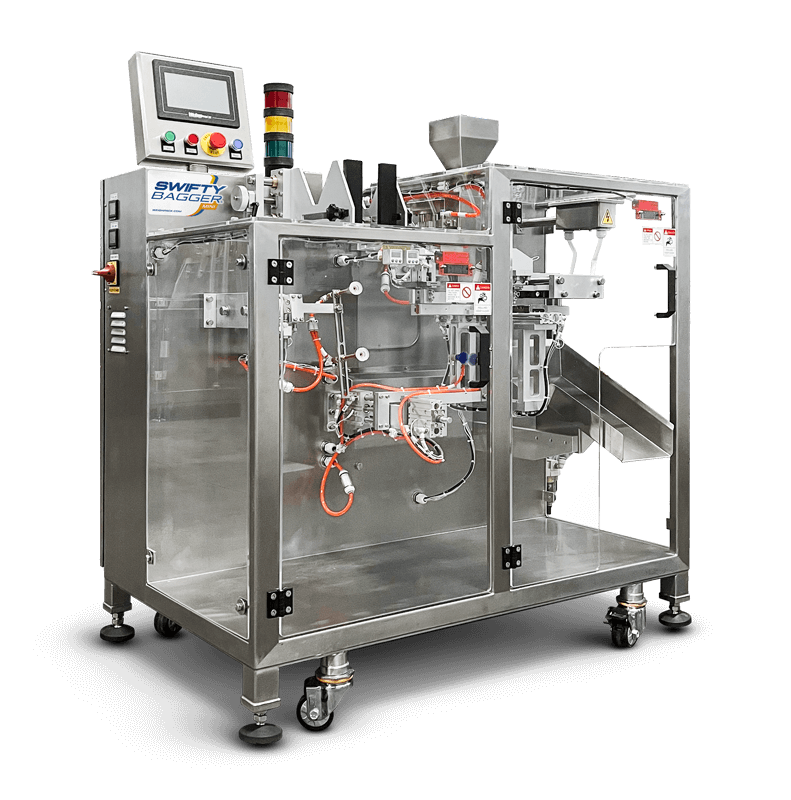

SWIFTY BAGGER MINI

COMPACT POUCH FILLING

Videos

The Swifty Bagger Mini stand-up pouch filling machine is perfect for compact bag sizes. The Mini automatically opens, fills and seals a variety of premade stand-up pouches. With our smallest footprint, this machine occupies only 10 square feet of floor space and easily rolls to fit within your existing production environment.

The Mini is constructed with stainless steel and is easy to use, easy to service and easy to maintain. It features an easy-to-adjust bag magazine for convenient feeding that ensures premade pouches enter the machine perfectly square, resulting in consistent output and seals.

The Swifty Bagger Mini easily integrates with any auxiliary filling machines including our PrimoCombi multi-head weigher, PrimoLinear net weigher and Star Auger for powder filling.

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

SWIFTY BAGGER JUNIOR

ONE PROCESS POUCH FILLING

Videos

The Swifty Junior pouch filling machine automatically opens, fills and seals premade stand-up pouches (SUP, SURP, DOY) in one process, making it easy to use and easy to integrate with multi-head weighing, net weighing and auger filling machines.

The Swifty Junior is extremely compact requiring only ten square feet of floor space and is perfect for small to medium production rates of up to 900 bags per hour.

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Jr is suited for all industries as your go to one process pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Jr is suited for all industries as your go to one process pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

SWIFTY BAGGER SIDE LOAD

HORIZONTAL POUCH FILLING

Our unique Swifty Bagger Side Load automatic bagging machine is engineered to load and fill pre-made pouches horizontally.

Loading product horizontally creates a distinct appearance within the pouch that works well for marketing pre-packaged snack foods and supplements as well as pet chews and is perfect for products that need to be oriented in a specific direction such as medical devices or printed materials.

Constructed with stainless steel, this machine features a quick bag loading station with vacuum mechanism, a color touch screen and a no bag-no fill sensor. The straight-flow design allows the operator to see the entire filling process from the front side of the machine.

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Straight-flow design makes accessibility of parts and allows the operator to see the entire filling process from the front

- Easy to clean by simply opening the front clear transparent doors of the machine and access all bag filling areas.

- Omron PLC

- Temperature controller

- Color touch screen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Side Load is suited for all industries as your go to horizontal pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

SWIFTY BAGGER BOX GUSSET

FOR SIDE GUSSET BAGS

Videos

Automatically fill side gusset bags with block bottom, with or without a pocket zipper with our Swifty Bagger Box Gusset.

Designed to automatically open, fill, tuck and seal side gusset bags, this unique machine features an easily accessible bag magazine, automatic zipper opener, integrated bag shaker and exit conveyor.

Perfect for packaging coffee and other powder or granule products when paired with our auger powder filler. Match it with our multi-head weigher or linear net weigher and the Box Gusset will also efficiently bag other products such as candy, nuts, baked and dry goods, jerky or even hardware and textiles.

Ask about designing a fully automated system to include our WeightCheQ check weigher and other downstream solutions such as case packing and palletizing.

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.