Introduction

Vitamin gummies are a popular and convenient way to supplement your daily intake of essential nutrients. They come in various shapes, colors, flavors, and sizes, and they appeal to both children and adults. However, have you ever wondered how these gummies are filled into plastic bottles and sealed, labeled, and packed for distribution? In this blog post, we will show you how Weighpack Systems Inc., the leading company in the world who builds packaging machines to fill gummies into bottles, does it with our state-of-the-art technologies. We will explain in point form how each of our machines work and why they are the best choice for your gummy bottling needs.

Bottle unscrambling machine

The first step in the bottling process is to unscramble the empty plastic bottles and orient them in the right direction. Our bottle unscrambling machine does this with the following features:

- It has a large hopper that can hold up to 500 bottles of different shapes and sizes.

- It has a rotating disc that picks up the bottles from the hopper and transfers them to a conveyor belt.

- It has a sensor that detects the orientation of the bottles and flips them if they are upside down.

- It has a speed control that adjusts the disc rotation and conveyor belt speed according to the production rate.

- It has a reject system that removes any damaged or defective bottles from the conveyor belt.

Multihead weighing machine

The next step in the bottling process is to weigh the gummies and dispense them into the bottles. Our multihead weighing machine does this with the following features:

- It has a vibrating feeder that spreads the gummies evenly on a distribution cone.

- It has a series of radial feeders that transport the gummies from the cone to the weigh hoppers.

- It has a set of load cells that measure the weight of the gummies in each hopper.

- It has a computer that calculates the optimal combination of hoppers to achieve the target weight for each bottle.

- It has a set of discharge chutes that open and close to release the gummies from the selected hoppers into the bottles.

Continuous indexing conveyor bottle filling machine

The next step in the bottling process is to fill the bottles with the gummies. Our continuous indexing conveyor bottle filling machine does this with the following features:

- It has a star wheel that indexes the bottles into the filling position.

- It has a pneumatic cylinder that lowers the filling head into the bottle neck.

- It has a servo motor that controls the filling speed and accuracy.

- It has a nozzle that dispenses the gummies into the bottle in a gentle and precise manner.

- It has a sensor that detects the fill level and stops the filling when the bottle is full.

Automatic rotary chuck style capping machine

The next step in the bottling process is to cap the bottles with the lids. Our automatic rotary chuck style capping machine does this with the following features:

- It has a cap sorter that feeds the lids into the cap chute.

- It has a cap elevator that lifts the lids from the chute to the cap pick-off station.

- It has a rotary turret that picks up the lids from the station and places them on the bottle necks.

- It has a set of chucks that tighten the lids on the bottle necks with the desired torque.

- It has a sensor that detects the presence and position of the lids and rejects any uncapped or misaligned bottles.

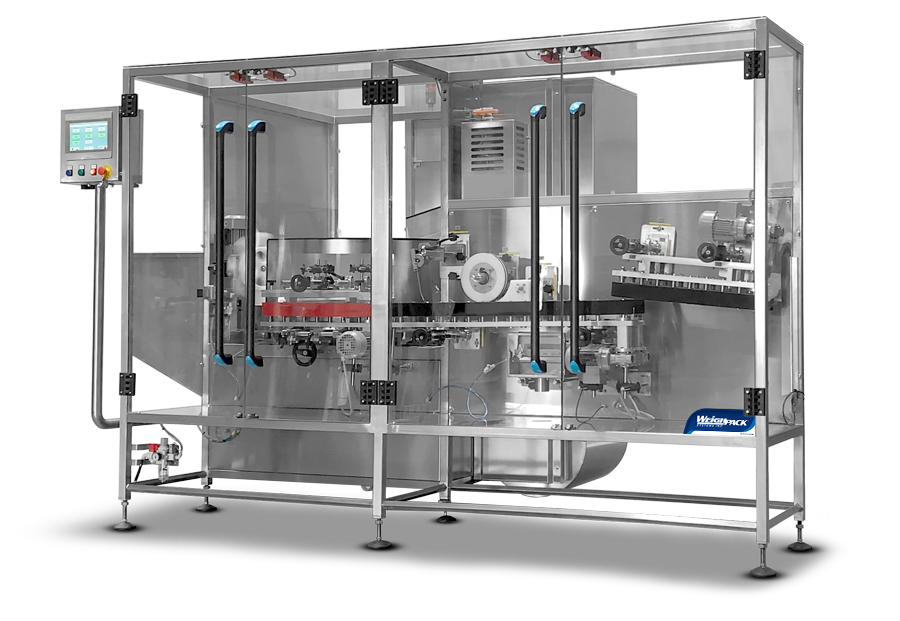

Adhesive labeling machine for bottles

The next step in the bottling process is to label the bottles with the product information and branding. Our adhesive labeling machine for bottles does this with the following features:

- It has a label roll holder that unwinds the labels from the roll.

- It has a label sensor that detects the label position and length.

- It has a label applicator that peels off the labels from the backing paper and applies them to the bottle surface.

- It has a label presser that smoothes out the labels and removes any air bubbles or wrinkles.

- It has a label encoder that prints the batch number and expiry date on the labels.

Bottle tray packing machine with gantry robot

The next step in the bottling process is to pack the bottles into trays for easy handling and transportation. Our bottle tray packing machine with gantry robot does this with the following features:

- It has a tray feeder that supplies the empty trays to the packing station.

- It has a gantry robot that picks up the bottles from the conveyor belt and places them into the trays according to the predefined pattern.

- It has a tray sealer that seals the trays with a plastic film to protect the bottles from dust and moisture.

- It has a tray stacker that stacks the trays on a pallet for easy loading and unloading.

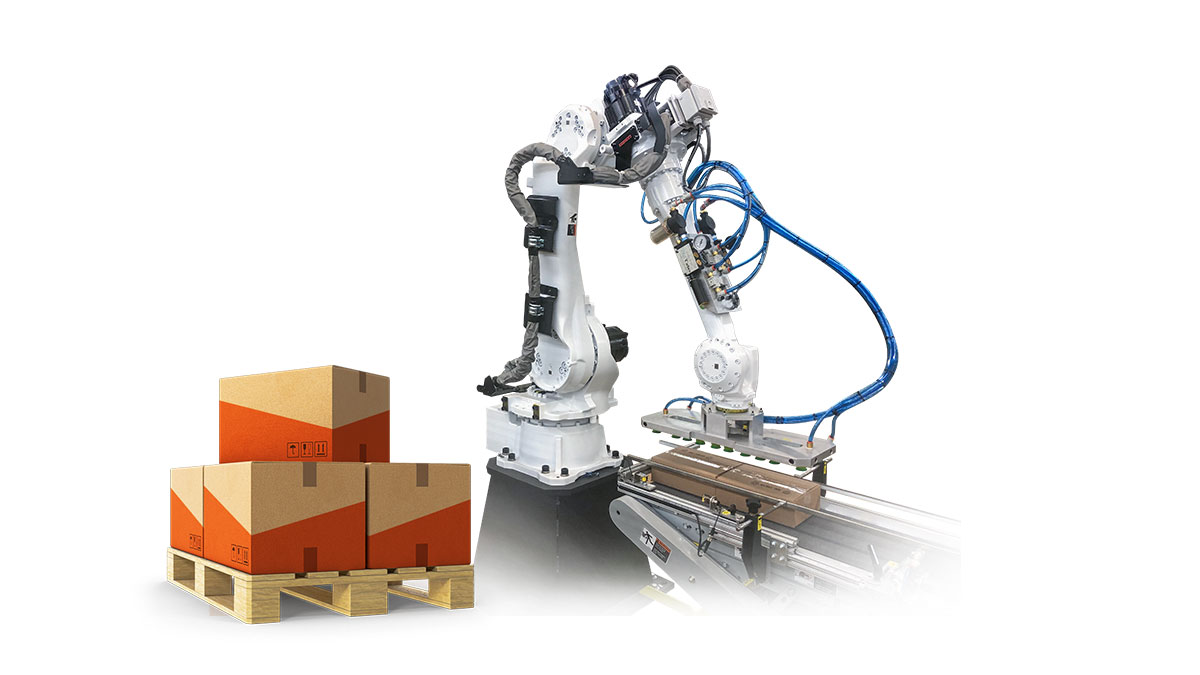

Robotic palletizing machine

The final step in the bottling process is to palletize the trays for storage and distribution. Our robotic palletizing machine does this with the following features:

- It has a pallet dispenser that feeds the empty pallets to the palletizing station.

- It has a robotic arm that picks up the trays from the tray stacker and places them on the pallets according to the predefined pattern.

- It has a pallet wrapper that wraps the pallets with a stretch film to secure the trays and prevent them from falling off.

- It has a pallet conveyor that transports the pallets to the warehouse or the loading dock.

Conclusion

We hope you enjoyed this blog post and learned something new about how Weighpack Systems Inc. fills vitamin gummies into bottles with our innovative packaging machines. We are proud to offer you the best solutions for your gummy bottling needs, with high speed, accuracy, efficiency, and reliability. We are also committed to providing you with excellent customer service and technical support, as well as customized options to suit your specific requirements. If you are interested in learning more about our products and services, please contact us: