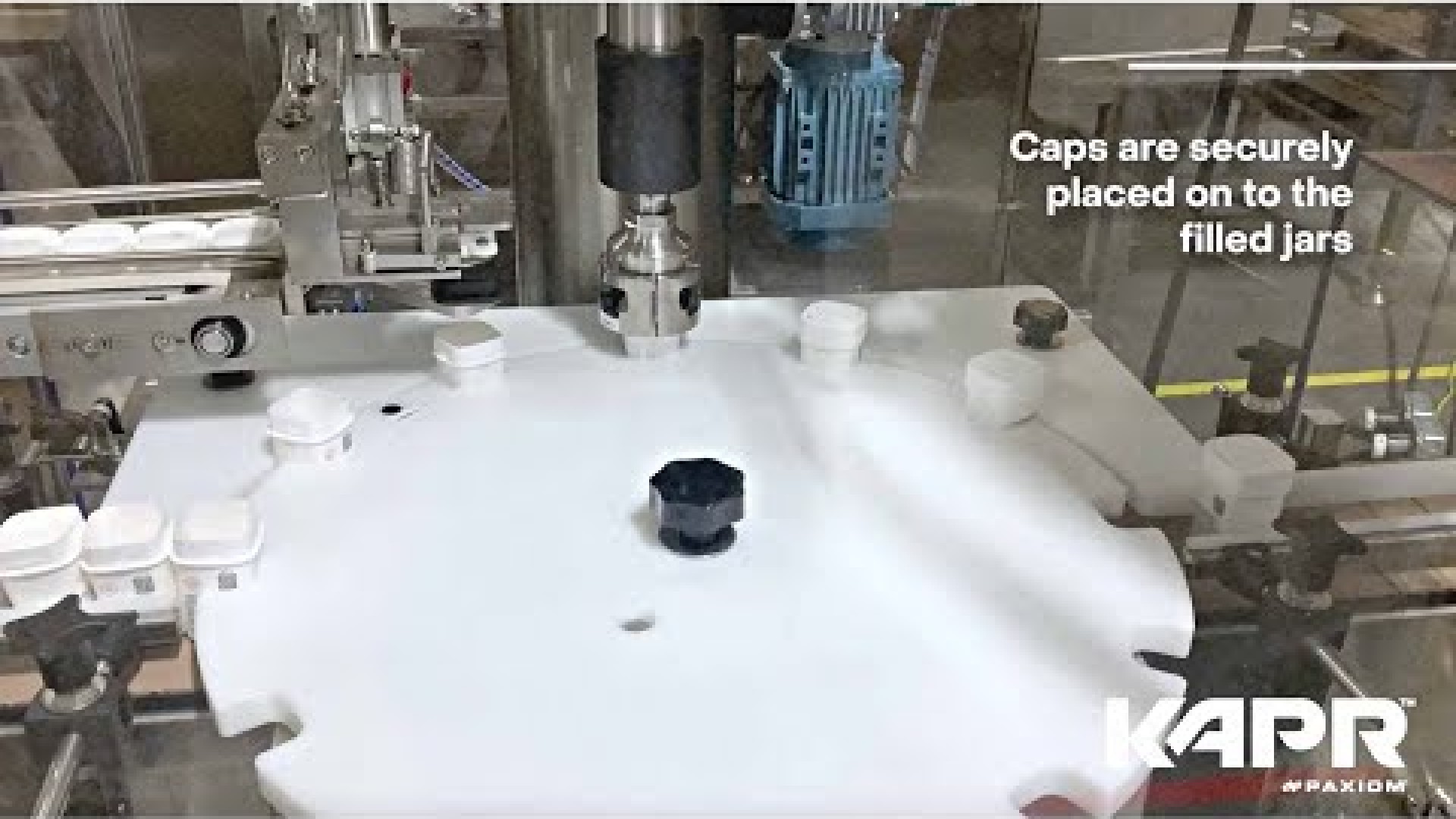

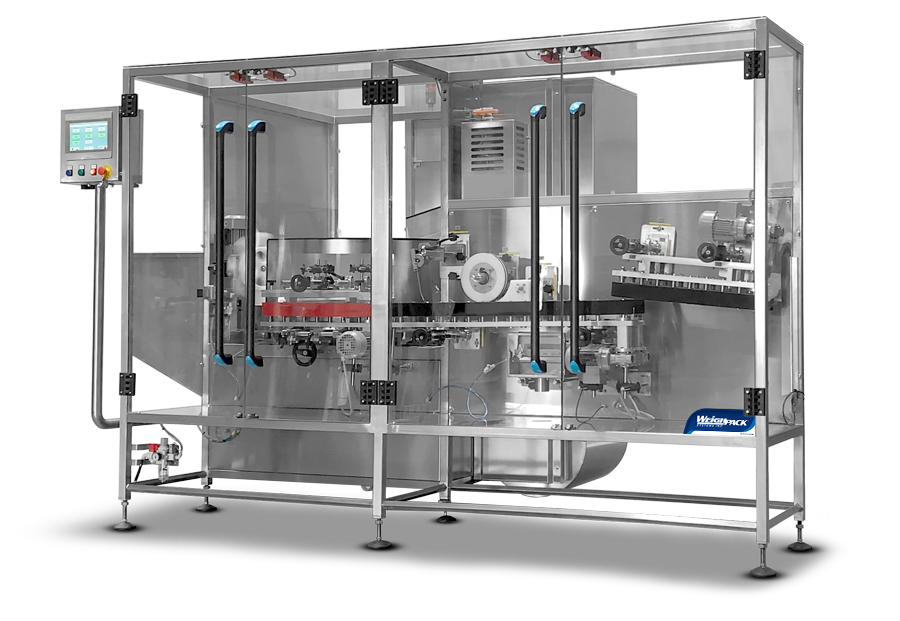

ROTARY CHUCK STYLE CAPPING

Automated Rotary Capping

Our family of automatic capping machine, ideal for medium to high speed requirements, is ideally suited for snack food, confectionery, beverage, pharmaceutical, cannabis, and numerous other industries where high efficiencies are required.

Offering multiple varieties of cappers, we are capable of accommodating various size containers and meeting production rates from 10 to 150 cycles/min (depending on the specifics of container and cap).

Videos

Features

- Stainless steel frame

- Compact footprint

- Easy open inspection doors complete with mechanical safety switches

- Inlet and outlet conveyor belts with single motorization

- Adjustable guides in stainless steel and polyethylene

- Two programmable speeds for approaching and closing in up/down movement

- Star wheel for container transport

- Closing unit for pressure caps

- Omron PLC

- Color touchscreen display

- Optional cap infeed conveyor designed to conveniently take bulk caps from floor level and automatically feed capping device.

Our Rotary Chuck Capping machines are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Features

Features

- Stainless steel frame

- Compact footprint

- Easy open inspection doors complete with mechanical safety switches

- Inlet and outlet conveyor belts with single motorization

- Adjustable guides in stainless steel and polyethylene

- Two programmable speeds for approaching and closing in up/down movement

- Star wheel for container transport

- Closing unit for pressure caps

- Omron PLC

- Color touchscreen display

- Optional cap infeed conveyor designed to conveniently take bulk caps from floor level and automatically feed capping device.

- Ideal Markets

Our Rotary Chuck Capping machines are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

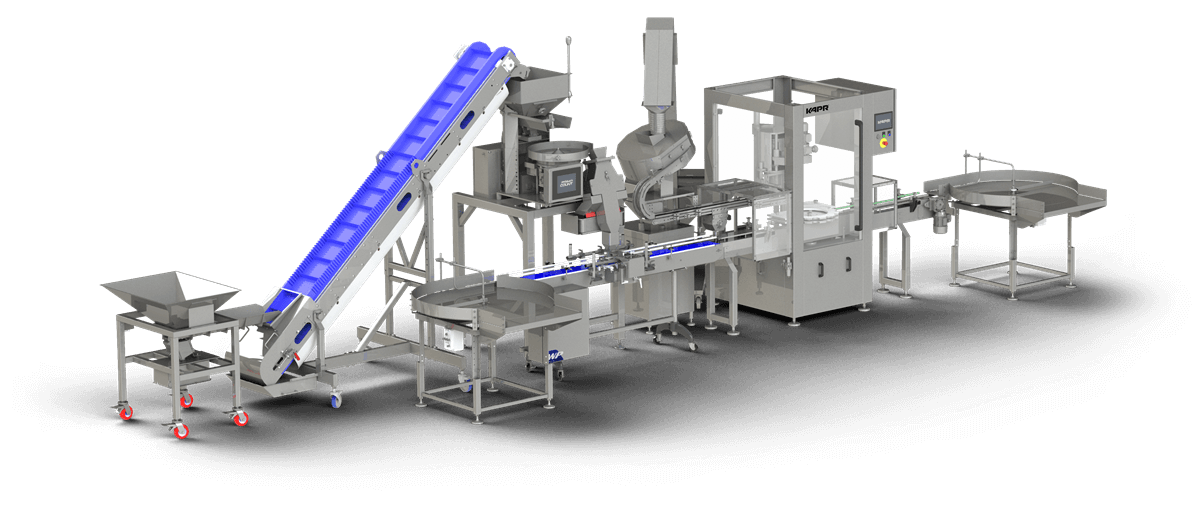

AUTOMATIC BOTTLE UNSCRAMBLING

Smooth Bottle Transferring

Our user-friendly bottle unscrambling machines will smoothly transfer your plastic bottles from the bulk supply bowl and feed them in-line to an indexing conveyor for downstream filling and packaging. These machines are compact and hygienic and applicable for many products including food, pharmaceuticals, nutraceuticals, and cosmetics.

Eliminating human intervention in the unscrambling process decreases the likelihood of bacteria buildup and cross-contamination.

Features

- Sturdy, stainless steel construction

- Compact foot print

- Easily configurable for various bottle shapes and sizes

- Quick change-over between bottle sizes

- Gentle bottle handling

- Integrated hopper sensors to detect / alert for low product levels

- Precise photo-eye to prevent backlogs and jams

- Harmonised control with the production line allowing the speed of the Bottle Unscrambler to match the line speed

- Open design for quick access to machine inner-workings• Interlocked safety guarding with automatic stopping of the machine

- Omron PLC

- Color touch screen display

Our automatic Bottle Unscrambling machine is suited for all industries as your go to bottle unscrambling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Sturdy, stainless steel construction

- Compact foot print

- Easily configurable for various bottle shapes and sizes

- Quick change-over between bottle sizes

- Gentle bottle handling

- Integrated hopper sensors to detect / alert for low product levels

- Precise photo-eye to prevent backlogs and jams

- Harmonised control with the production line allowing the speed of the Bottle Unscrambler to match the line speed

- Open design for quick access to machine inner-workings• Interlocked safety guarding with automatic stopping of the machine

- Omron PLC

- Color touch screen display

- Ideal Markets

Our automatic Bottle Unscrambling machine is suited for all industries as your go to bottle unscrambling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

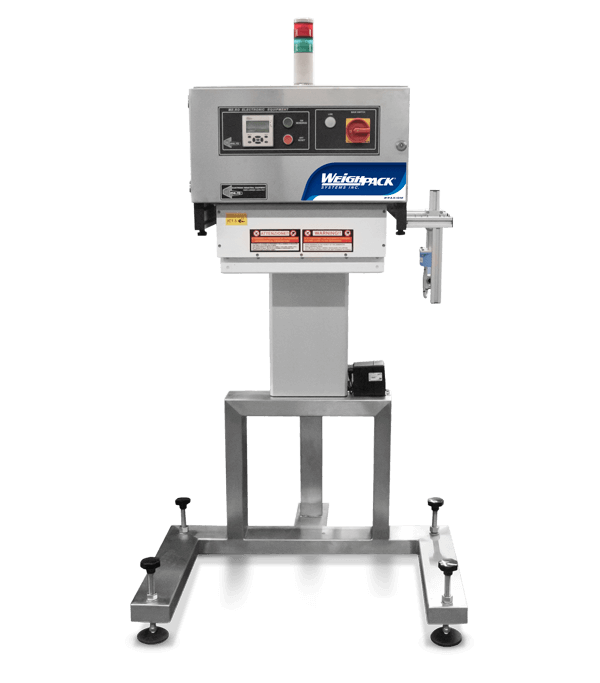

CAP INDUCTION SEALING

Compact Sealing

The cap induction sealing machine offers leak guarding and tamper evidence while preserving freshness and prolonging shelf life. This user-friendly machine is compact, efficient and can seal both plastic and glass bottles of various shapes and sizes.

Our induction sealing machine is perfectly suited for food, beverage, cosmetic, chemical, pharmaceutical, nutraceutical industries and many other related applications.

Videos

Features

- Aluminum foil detector

- Missing foil sets off alarm and consequently rejects container to an inspection table

- Automated height adjustment for different container heights

- High efficiency due to the configuration of the power circuits using IGBT modules

- Short circuit electronic protection on inverter power modules

- Construction according to norm EN-60204-1

- Electromagnetic compatibility (EMC) in accordance with norms EN-5511 and EN-50082-2

- Optical or acoustic device for alarm signaling regarding generator issues

- Continuous green light signaling generator ON, intermittent red light in case of alarm

- Interblock and auxiliary control switches for possible utilization on the filling line in case of generator malfunctioning or exclusion of the containers without aluminum foil

- Control panel with microprocessor monitoring and displaying work magnitudes and alarm signals

Our Induction Sealing machine is suited for all industries as your go to cap induction sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Aluminum foil detector

- Missing foil sets off alarm and consequently rejects container to an inspection table

- Automated height adjustment for different container heights

- High efficiency due to the configuration of the power circuits using IGBT modules

- Short circuit electronic protection on inverter power modules

- Construction according to norm EN-60204-1

- Electromagnetic compatibility (EMC) in accordance with norms EN-5511 and EN-50082-2

- Optical or acoustic device for alarm signaling regarding generator issues

- Continuous green light signaling generator ON, intermittent red light in case of alarm

- Interblock and auxiliary control switches for possible utilization on the filling line in case of generator malfunctioning or exclusion of the containers without aluminum foil

- Control panel with microprocessor monitoring and displaying work magnitudes and alarm signals

- Ideal Markets

Our Induction Sealing machine is suited for all industries as your go to cap induction sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

ROTARY CHUCK STYLE CAPPING

Automated Rotary Capping

Videos

Our family of automatic capping machine, ideal for medium to high speed requirements, is ideally suited for snack food, confectionery, beverage, pharmaceutical, cannabis, and numerous other industries where high efficiencies are required.

Offering multiple varieties of cappers, we are capable of accommodating various size containers and meeting production rates from 10 to 150 cycles/min (depending on the specifics of container and cap).

Features

- Stainless steel frame

- Compact footprint

- Easy open inspection doors complete with mechanical safety switches

- Inlet and outlet conveyor belts with single motorization

- Adjustable guides in stainless steel and polyethylene

- Two programmable speeds for approaching and closing in up/down movement

- Star wheel for container transport

- Closing unit for pressure caps

- Omron PLC

- Color touchscreen display

- Optional cap infeed conveyor designed to conveniently take bulk caps from floor level and automatically feed capping device.

Our Rotary Chuck Capping machines are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame

- Compact footprint

- Easy open inspection doors complete with mechanical safety switches

- Inlet and outlet conveyor belts with single motorization

- Adjustable guides in stainless steel and polyethylene

- Two programmable speeds for approaching and closing in up/down movement

- Star wheel for container transport

- Closing unit for pressure caps

- Omron PLC

- Color touchscreen display

- Optional cap infeed conveyor designed to conveniently take bulk caps from floor level and automatically feed capping device.

- Ideal Markets

Our Rotary Chuck Capping machines are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

AUTOMATIC BOTTLE UNSCRAMBLING

Smooth Bottle Transferring

Our user-friendly bottle unscrambling machines will smoothly transfer your plastic bottles from the bulk supply bowl and feed them in-line to an indexing conveyor for downstream filling and packaging. These machines are compact and hygienic and applicable for many products including food, pharmaceuticals, nutraceuticals, and cosmetics.

Eliminating human intervention in the unscrambling process decreases the likelihood of bacteria buildup and cross-contamination.

Features

- Sturdy, stainless steel construction

- Compact foot print

- Easily configurable for various bottle shapes and sizes

- Quick change-over between bottle sizes

- Gentle bottle handling

- Integrated hopper sensors to detect / alert for low product levels

- Precise photo-eye to prevent backlogs and jams

- Harmonised control with the production line allowing the speed of the Bottle Unscrambler to match the line speed

- Open design for quick access to machine inner-workings• Interlocked safety guarding with automatic stopping of the machine

- Omron PLC

- Color touch screen display

Our automatic Bottle Unscrambling machine is suited for all industries as your go to bottle unscrambling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specification

Features

- Sturdy, stainless steel construction

- Compact foot print

- Easily configurable for various bottle shapes and sizes

- Quick change-over between bottle sizes

- Gentle bottle handling

- Integrated hopper sensors to detect / alert for low product levels

- Precise photo-eye to prevent backlogs and jams

- Harmonised control with the production line allowing the speed of the Bottle Unscrambler to match the line speed

- Open design for quick access to machine inner-workings• Interlocked safety guarding with automatic stopping of the machine

- Omron PLC

- Color touch screen display

- Ideal Markets

Our automatic Bottle Unscrambling machine is suited for all industries as your go to bottle unscrambling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

CAP INDUCTION SEALING

Compact Bottle Sealing

Videos

The cap induction sealing machine offers leak guarding and tamper evidence while preserving freshness and prolonging shelf life. This user-friendly machine is compact, efficient and can seal both plastic and glass bottles of various shapes and sizes.

Our induction sealing machine is perfectly suited for food, beverage, cosmetic, chemical, pharmaceutical, nutraceutical industries and many other related applications.

Features

- Aluminum foil detector

- Missing foil sets off alarm and consequently rejects container to an inspection table

- Automated height adjustment for different container heights

- High efficiency due to the configuration of the power circuits using IGBT modules

- Short circuit electronic protection on inverter power modules

- Construction according to norm EN-60204-1

- Electromagnetic compatibility (EMC) in accordance with norms EN-5511 and EN-50082-2

- Optical or acoustic device for alarm signaling regarding generator issues

- Continuous green light signaling generator ON, intermittent red light in case of alarm

- Interblock and auxiliary control switches for possible utilization on the filling line in case of generator malfunctioning or exclusion of the containers without aluminum foil

- Control panel with microprocessor monitoring and displaying work magnitudes and alarm signals

Our Induction Sealing machine is suited for all industries as your go to cap induction sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specification

Features

- Aluminum foil detector

- Missing foil sets off alarm and consequently rejects container to an inspection table

- Automated height adjustment for different container heights

- High efficiency due to the configuration of the power circuits using IGBT modules

- Short circuit electronic protection on inverter power modules

- Construction according to norm EN-60204-1

- Electromagnetic compatibility (EMC) in accordance with norms EN-5511 and EN-50082-2

- Optical or acoustic device for alarm signaling regarding generator issues

- Continuous green light signaling generator ON, intermittent red light in case of alarm

- Interblock and auxiliary control switches for possible utilization on the filling line in case of generator malfunctioning or exclusion of the containers without aluminum foil

- Control panel with microprocessor monitoring and displaying work magnitudes and alarm signals

- Ideal Markets

Our Induction Sealing machine is suited for all industries as your go to cap induction sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.