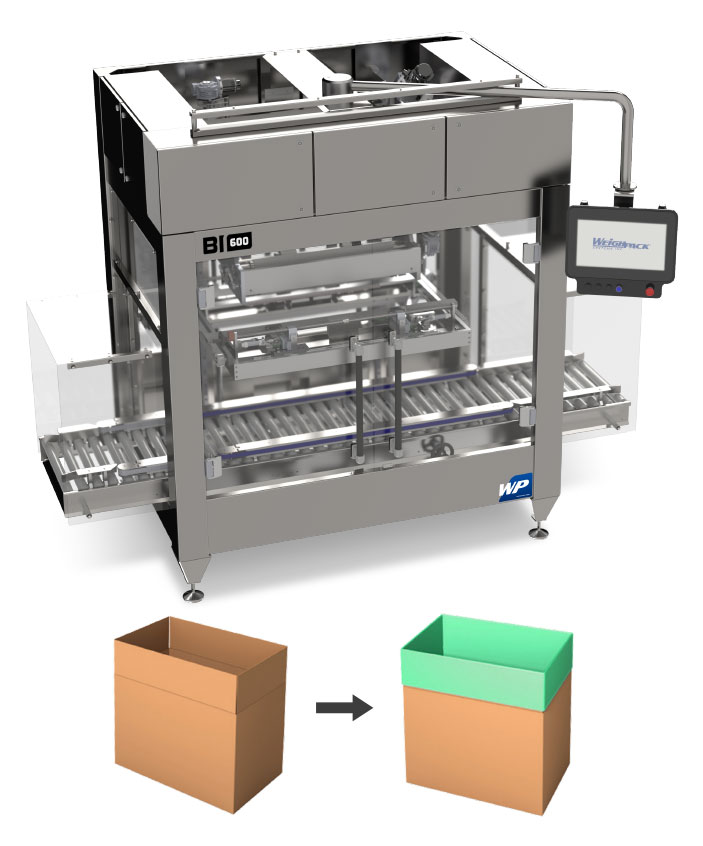

BI 600

Automated Bag Inserter

We have the solution for bagging your bulk quantities of pet food, frozen food, snacks, wrapped candy and much more with this workhorse system.

The BI 600 bag inserter dispenses film on a roll, cuts, seals and then inserts the bag into the case. Once the product is weighed and filled, using a V25 bulk weigh filler, the case passes to the BU 600 bag uncuffer.

Videos

| Parts | Description |

|---|---|

| Box/Tray Length | 300 – 610mm |

| Box/Tray Width | 200 – 410mm |

| Box/Tray Height | 250 – 650mm |

| Film Roll Max Width | 650mm |

| Film Roll Max Diameter | 510mm |

| Film Roll Thickness | 1 – 4mil |

| Tubing Roll Film Width | box/tray length + 16 mm |

| Tubing Roll Film Gusset | box/tray width + 45 mm |

| Tubing Roll Film Fold-Over | 140 – 180 mm |

Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo with absolute encoders

• Hiwin linear bearings

• Impulse sealing for leakproof polyethylene or laminated bags

(1 sealing line, 2-sided active sealing wire)

• V-shaped guillotine knife

• Caseflapholders

• Adjustment indicators

• Light stack – Audible with multicolor

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Features

Parts Description Box/Tray Length 300 – 610mm Box/Tray Width 200 – 410mm Box/Tray Height 250 – 650mm Film Roll Max Width 650mm Film Roll Max Diameter 510mm Film Roll Thickness 1 – 4mil Tubing Roll Film Width box/tray length + 16 mm Tubing Roll Film Gusset box/tray width + 45 mm Tubing Roll Film Fold-Over 140 – 180 mm Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo with absolute encoders

• Hiwin linear bearings

• Impulse sealing for leakproof polyethylene or laminated bags

(1 sealing line, 2-sided active sealing wire)

• V-shaped guillotine knife

• Caseflapholders

• Adjustment indicators

• Light stack – Audible with multicolor- Ideal Markets

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

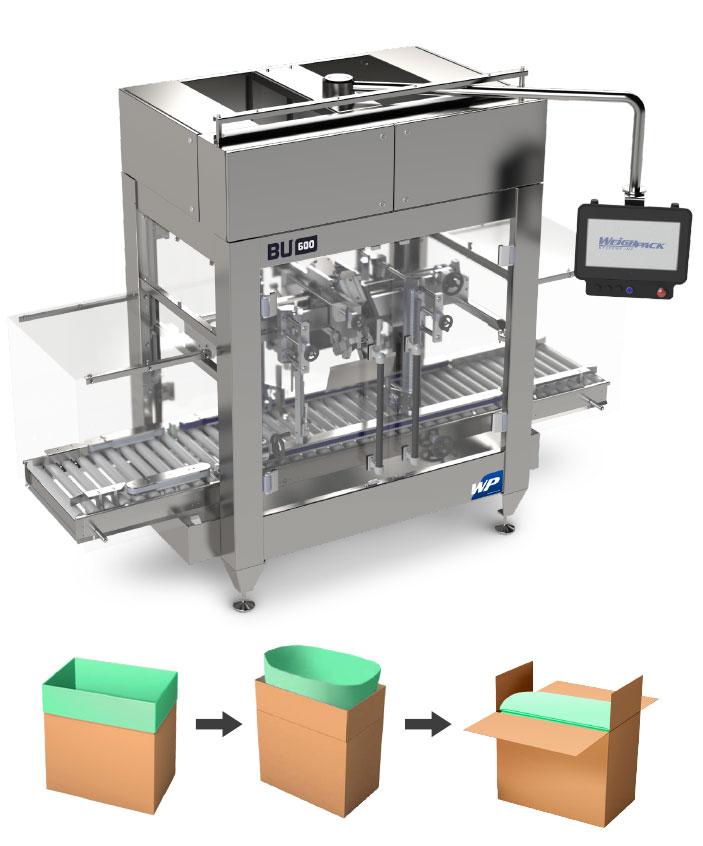

BU 600

Automated Bag Uncuffer

After passing through the BI 600, the bag is then uncuffed from the case and folded over the product prior to your box being conveyed to the next phase of the packaging process. Bag sealing and vacuum assemblies are also available.

This system can be completed by our sister brand, EndFlex, using their Boxxer case erector to form the case prior to bag insertion and their EZ Tape case sealer after bag uncuffing. Then the Z.Zag robotic palletizer can be added to fully automate your bulk bagging line.

| Parts | Description |

|---|---|

| Box/Tray Length | 300 – 610mm |

| Box/Tray Width | 200 – 410mm |

| Box/Tray Height | 250 – 650mm |

| Recommended Bag Fold-Over | 300 – 610mm |

| Film Roll Max Diameter | 510mm |

| Film Roll Thickness | 1 – 4mil |

| Tubing Roll Film Width | box/tray length + 16 mm |

| Tubing Roll Film Gusset | box/tray width + 45 mm |

Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo motors with absolute encoders

• Hiwin linear bearings

• Case lap holders

• Adjustment indicators

• Bag folding device

• Light stack – Audible with multicolor

Our BU 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Parts Description Box/Tray Length 300 – 610mm Box/Tray Width 200 – 410mm Box/Tray Height 250 – 650mm Recommended Bag Fold-Over 300 – 610mm Film Roll Max Diameter 510mm Film Roll Thickness 1 – 4mil Tubing Roll Film Width box/tray length + 16 mm Tubing Roll Film Gusset box/tray width + 45 mm Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo motors with absolute encoders

• Hiwin linear bearings

• Case lap holders

• Adjustment indicators

• Bag folding device

• Light stack – Audible with multicolor- Ideal Markets

Our BU 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

BUSV 600

Automated Bag Uncuffer & Vacuum Sealer

Vacuum sealing is a crucial process in food preservation. By removing air from the packaging, it significantly extends the shelf life of food products, preventing spoilage and maintaining freshness. After passing through the BI 600, a bag line tote is then uncuffed from the case and folded over the product prior to your box being conveyed to the next phase of the packaging process. The bag is then vacuum sealed before moving on.

Videos

Features

- 18-Inch Touch Screen with PLC: The BUSV-600 is equipped with an 18-inch touch screen interface integrated with a Programmable Logic Controller (PLC). This user-friendly system allows for easy operation and precise control over the vacuum sealing process.

- Stainless Steel Construction: Built with high-grade stainless steel, the BUSV-600 ensures durability and longevity. This robust construction is resistant to corrosion and easy to clean, making it ideal for food processing environments.

- Heavy Duty Frame: The BUSV-600 features a heavy-duty frame that provides stability and strength, supporting high-volume operations without compromising performance.

- Affordable Price: Despite its advanced features, the BUSV-600 is offered at an affordable price, making it accessible to businesses of all sizes. WeighPack Systems Inc. is committed to providing cost-effective solutions without sacrificing quality.

*Rates subject to package style, type and size

Our BUSV 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 18-Inch Touch Screen with PLC: The BUSV-600 is equipped with an 18-inch touch screen interface integrated with a Programmable Logic Controller (PLC). This user-friendly system allows for easy operation and precise control over the vacuum sealing process.

- Stainless Steel Construction: Built with high-grade stainless steel, the BUSV-600 ensures durability and longevity. This robust construction is resistant to corrosion and easy to clean, making it ideal for food processing environments.

- Heavy Duty Frame: The BUSV-600 features a heavy-duty frame that provides stability and strength, supporting high-volume operations without compromising performance.

- Affordable Price: Despite its advanced features, the BUSV-600 is offered at an affordable price, making it accessible to businesses of all sizes. WeighPack Systems Inc. is committed to providing cost-effective solutions without sacrificing quality.

*Rates subject to package style, type and size

- Ideal Markets

Our BUSV 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

BI 600

Automated Bag Inserting

We have the solution for bagging your bulk quantities of pet food, frozen food, snacks, wrapped candy and much more with this workhorse system.

The BI 600 bag inserter dispenses film on a roll, cuts, seals and then inserts the bag into the case. Once the product is weighed and filled, using a V25 bulk weigh filler, the case passes to the BU 600 bag uncuffer.

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

| Parts | Description |

|---|---|

| Box/Tray Length | 300 – 610mm |

| Box/Tray Width | 200 – 410mm |

| Box/Tray Height | 250 – 650mm |

| Film Roll Max Width | 650mm |

| Film Roll Max Diameter | 510mm |

| Film Roll Thickness | 1 – 4mil |

| Tubing Roll Film Width | box/tray length + 16 mm |

| Tubing Roll Film Gusset | box/tray width + 45 mm |

| Tubing Roll Film Fold-Over | 140 – 180 mm |

Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo with absolute encoders

• Hiwin linear bearings

• Impulse sealing for leakproof polyethylene or laminated bags

(1 sealing line, 2-sided active sealing wire)

• V-shaped guillotine knife

• Caseflapholders

• Adjustment indicators

• Light stack – Audible with multicolor

- Ideal Markets

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Parts Description Box/Tray Length 300 – 610mm Box/Tray Width 200 – 410mm Box/Tray Height 250 – 650mm Film Roll Max Width 650mm Film Roll Max Diameter 510mm Film Roll Thickness 1 – 4mil Tubing Roll Film Width box/tray length + 16 mm Tubing Roll Film Gusset box/tray width + 45 mm Tubing Roll Film Fold-Over 140 – 180 mm Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo with absolute encoders

• Hiwin linear bearings

• Impulse sealing for leakproof polyethylene or laminated bags

(1 sealing line, 2-sided active sealing wire)

• V-shaped guillotine knife

• Caseflapholders

• Adjustment indicators

• Light stack – Audible with multicolor

BU 600

Automated Bag Uncuffing

After passing through the BI 600, the bag is then uncuffed from the case and folded over the product prior to your box being conveyed to the next phase of the packaging process. Bag sealing and vacuum assemblies are also available.

This system can be completed by our sister brand, EndFlex, using their Boxxer case erector to form the case prior to bag insertion and their EZ Tape case sealer after bag uncuffing. Then the Z.Zag robotic palletizer can be added to fully automate your bulk bagging line.

| Parts | Description |

|---|---|

| Box/Tray Length | 300 – 610mm |

| Box/Tray Width | 200 – 410mm |

| Box/Tray Height | 250 – 650mm |

| Recommended Bag Fold-Over | 300 – 610mm |

| Film Roll Max Diameter | 510mm |

| Film Roll Thickness | 1 – 4mil |

| Tubing Roll Film Width | box/tray length + 16 mm |

| Tubing Roll Film Gusset | box/tray width + 45 mm |

Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo motors with absolute encoders

• Hiwin linear bearings

• Case lap holders

• Adjustment indicators

• Bag folding device

• Light stack – Audible with multicolor

Our BU 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specification

Parts Description Box/Tray Length 300 – 610mm Box/Tray Width 200 – 410mm Box/Tray Height 250 – 650mm Recommended Bag Fold-Over 300 – 610mm Film Roll Max Diameter 510mm Film Roll Thickness 1 – 4mil Tubing Roll Film Width box/tray length + 16 mm Tubing Roll Film Gusset box/tray width + 45 mm Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo motors with absolute encoders

• Hiwin linear bearings

• Case lap holders

• Adjustment indicators

• Bag folding device

• Light stack – Audible with multicolor- Ideal Markets

Our BU 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

BUSV 600

Automated Bag Uncuffing & Vacuum Sealing

Vacuum sealing is a crucial process in food preservation. By removing air from the packaging, it significantly extends the shelf life of food products, preventing spoilage and maintaining freshness. After passing through the BI 600, a bag line tote is then uncuffed from the case and folded over the product prior to your box being conveyed to the next phase of the packaging process. The bag is then vacuum sealed before moving on.

Videos

Features

- 18-Inch Touch Screen with PLC: The BUSV-600 is equipped with an 18-inch touch screen interface integrated with a Programmable Logic Controller (PLC). This user-friendly system allows for easy operation and precise control over the vacuum sealing process.

- Stainless Steel Construction: Built with high-grade stainless steel, the BUSV-600 ensures durability and longevity. This robust construction is resistant to corrosion and easy to clean, making it ideal for food processing environments.

- Heavy Duty Frame: The BUSV-600 features a heavy-duty frame that provides stability and strength, supporting high-volume operations without compromising performance.

- Affordable Price: Despite its advanced features, the BUSV-600 is offered at an affordable price, making it accessible to businesses of all sizes. WeighPack Systems Inc. is committed to providing cost-effective solutions without sacrificing quality.

*Rates subject to package style, type and size

Our BUSV 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specification

Features

- 18-Inch Touch Screen with PLC: The BUSV-600 is equipped with an 18-inch touch screen interface integrated with a Programmable Logic Controller (PLC). This user-friendly system allows for easy operation and precise control over the vacuum sealing process.

- Stainless Steel Construction: Built with high-grade stainless steel, the BUSV-600 ensures durability and longevity. This robust construction is resistant to corrosion and easy to clean, making it ideal for food processing environments.

- Heavy Duty Frame: The BUSV-600 features a heavy-duty frame that provides stability and strength, supporting high-volume operations without compromising performance.

- Affordable Price: Despite its advanced features, the BUSV-600 is offered at an affordable price, making it accessible to businesses of all sizes. WeighPack Systems Inc. is committed to providing cost-effective solutions without sacrificing quality.

*Rates subject to package style, type and size

- Ideal Markets

Our BUSV 600 is suited for all industries as your go to bag uncuffing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.