WeightCheQ 0-250

High Accuracy Check Weighing

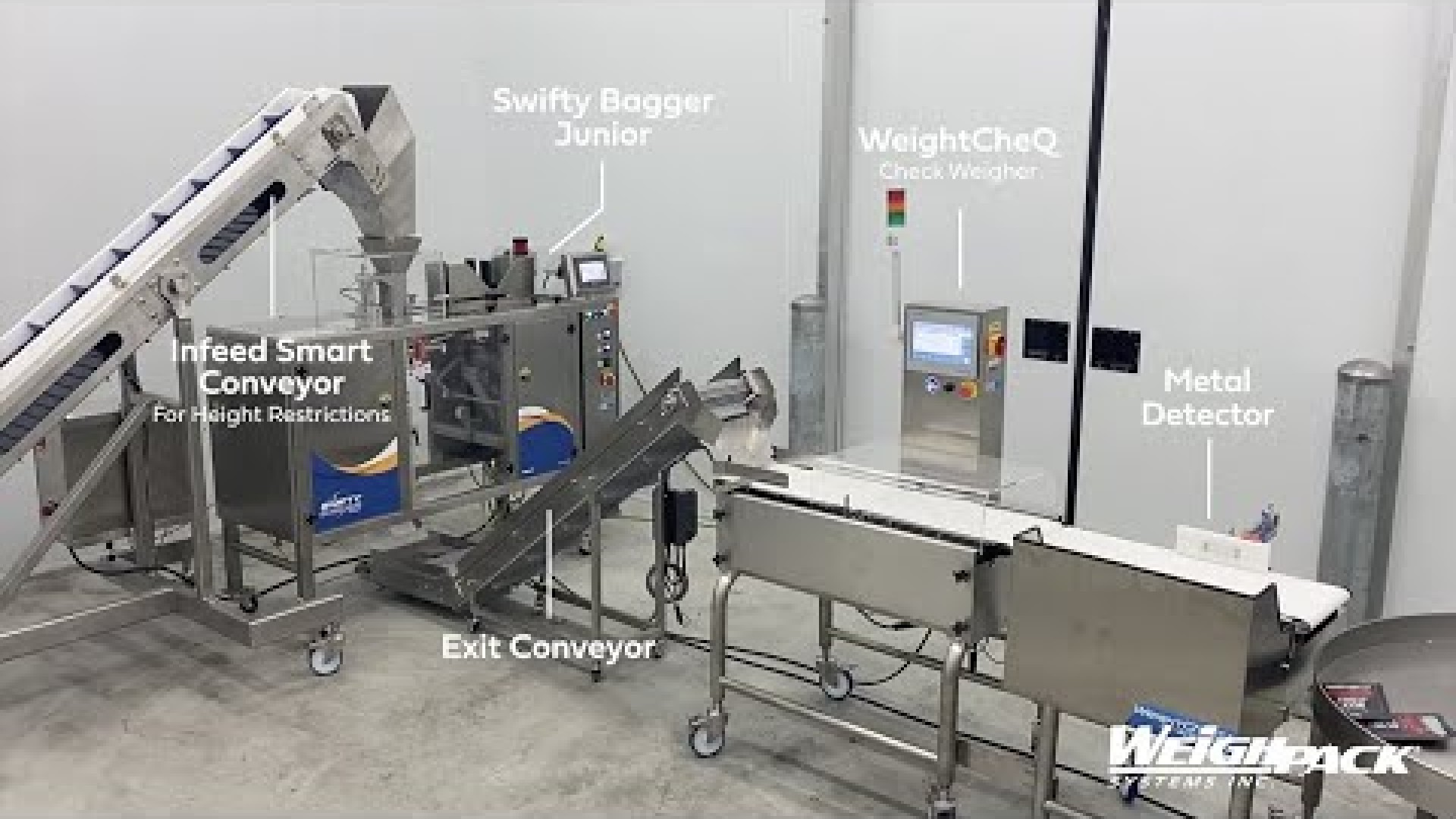

The industry-leading WeightCheQ™ series of check weighers offers speed, accuracy and easy operation. These machines can be used to check the weight of a variety of packages including bags, bottles, cartons and cases and are easily integrated into existing packaging systems where automatic bagging, container filling, flow wrapping and case filling is performed.

| Parts | Description |

|---|---|

| Material of Frame | 304 Stainless steel |

| Weighing range (g) | 0 – 250 |

| Best accuracy (g) | ±0.01 |

Features

• Electromagnetic force restoration (EMFR) weigh cell

• Complete stainless steel/aluminum construction

• Heavy-duty frame structure

• Heavy-duty CNC machined foot pads

• High precision load cell

• Modular frame design

• Product accumulation drawer

• Food grade belts

• Anti-static Lexan safety guard

• Rejection system

• No changeover parts required

• Multi-color warning light with buzzer

• No compressed air required

What is EMFR?

Electromagnetic force restoration (EMFR) combines electrical and mechanical components. The design of EMFR weigh cells is based on a balance mechanism. It consists of a position indicator, a controller and an electro-magnetic drive (coil and permanent magnet). In its functionality, the Weigh Cell can be compared to a simple beam balance. If a weight is placed on one side of the beam, the opposite side of the weighing beam attempts to move out of the magnet’s magnetic field. The position indicator detects this deviation and the amount of current required for balancing the beam and ensuring that no position change can occur is transmitted through the coil. As the current is proportional to the weight and can be measured via a resistor, it can be converted into a digital signal which is used for further processing.

Our WeightCheq 0-250 is suited for all industries as your go to high accuracy check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Parts Description Material of Frame 304 Stainless steel Weighing range (g) 0 – 250 Best accuracy (g) ±0.01 Features

• Electromagnetic force restoration (EMFR) weigh cell

• Complete stainless steel/aluminum construction

• Heavy-duty frame structure

• Heavy-duty CNC machined foot pads

• High precision load cell

• Modular frame design

• Product accumulation drawer

• Food grade belts

• Anti-static Lexan safety guard

• Rejection system

• No changeover parts required

• Multi-color warning light with buzzer

• No compressed air requiredWhat is EMFR?

Electromagnetic force restoration (EMFR) combines electrical and mechanical components. The design of EMFR weigh cells is based on a balance mechanism. It consists of a position indicator, a controller and an electro-magnetic drive (coil and permanent magnet). In its functionality, the Weigh Cell can be compared to a simple beam balance. If a weight is placed on one side of the beam, the opposite side of the weighing beam attempts to move out of the magnet’s magnetic field. The position indicator detects this deviation and the amount of current required for balancing the beam and ensuring that no position change can occur is transmitted through the coil. As the current is proportional to the weight and can be measured via a resistor, it can be converted into a digital signal which is used for further processing.

- Ideal Markets

Our WeightCheq 0-250 is suited for all industries as your go to high accuracy check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

WeightCheQ 3-100

Automatic Check Weighing

The industry-leading WeightCheQ™ series of check weighers offers speed, accuracy and easy operation. These machines can be used to check the weight of a variety of packages including bags, bottles, cartons and cases and are easily integrated into existing packaging systems where automatic bagging, container filling, flow wrapping and case filling is performed.

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch• With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

| Parts | Description |

|---|---|

| Material of Frame | 304 Stainless steel |

| Weighing range (g) | 3 – 100 |

| Minimum scale (g) | 0.1 |

| Best accuracy (g) | ±0.2 |

| Max throughput (pcs/min) | 150 |

| Width of weighing belt (mm) | 220 |

| Length of weighing belt (mm) | 450 |

| Height of conveyor belt (mm) | 780-900 |

| Direction of throughput | From left to right when facing control panel |

| Alarm mode | Audible and visual |

| Reject device | Default: Air pusher Option: Flipper |

| Power | 240V 1 Phase |

| Working environments | Free of obvious vibration and air flow |

Our WeightCheq 3-100 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch• With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

Parts Description Material of Frame 304 Stainless steel Weighing range (g) 3 – 100 Minimum scale (g) 0.1 Best accuracy (g) ±0.2 Max throughput (pcs/min) 150 Width of weighing belt (mm) 220 Length of weighing belt (mm) 450 Height of conveyor belt (mm) 780-900 Direction of throughput From left to right when facing control panel Alarm mode Audible and visual Reject device Default: Air pusher

Option: FlipperPower 240V 1 Phase Working environments Free of obvious vibration and air flow - Ideal Markets

Our WeightCheq 3-100 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

WeightCheQ 10-4000

Automatic Check Weighing

The industry-leading WeightCheQ™ series of check weighers offers speed, accuracy and easy operation. These machines can be used to check the weight of a variety of packages including bags, bottles, cartons and cases and are easily integrated into existing packaging systems where automatic bagging, container filling, flow wrapping and case filling is performed.

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch

- With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

| Parts | Description |

|---|---|

| Material of Frame | 304 Stainless steel |

| Weighing range (g) | 10 – 4000 |

| Minimum scale (g) | 0.1 |

| Best accuracy (g) | ±1 |

| Max throughput (pcs/min) | 90 |

| Width of weighing belt (mm) | 300 |

| Length of weighing belt (mm) | 550 |

| Height of conveyor belt (mm) | 780-900 |

| Direction of throughput | From left to right when facing control panel |

| Alarm mode | Audible and visual |

| Reject device | Default: Air pusher Option: Flipper |

| Power | 240V 1 Phase |

| Working environments | Free of obvious vibration and air flow |

Our WeightCheq 10-4000 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch

- With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

Parts Description Material of Frame 304 Stainless steel Weighing range (g) 10 – 4000 Minimum scale (g) 0.1 Best accuracy (g) ±1 Max throughput (pcs/min) 90 Width of weighing belt (mm) 300 Length of weighing belt (mm) 550 Height of conveyor belt (mm) 780-900 Direction of throughput From left to right when facing control panel Alarm mode Audible and visual Reject device Default: Air pusher

Option: FlipperPower 240V 1 Phase Working environments Free of obvious vibration and air flow - Ideal Markets

Our WeightCheq 10-4000 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

WeightCheQ 0-250

High Accuracy Check Weighing

The industry-leading WeightCheQ™ series of check weighers offers speed, accuracy and easy operation. These machines can be used to check the weight of a variety of packages including bags, bottles, cartons and cases and are easily integrated into existing packaging systems where automatic bagging, container filling, flow wrapping and case filling is performed.

| Parts | Description |

|---|---|

| Material of Frame | 304 Stainless steel |

| Weighing range (g) | 0 – 250 |

| Best accuracy (g) | ±0.01 |

Features

• Electromagnetic force restoration (EMFR) weigh cell

• Complete stainless steel/aluminum construction

• Heavy-duty frame structure

• Heavy-duty CNC machined foot pads

• High precision load cell

• Modular frame design

• Product accumulation drawer

• Food grade belts

• Anti-static Lexan safety guard

• Rejection system

• No changeover parts required

• Multi-color warning light with buzzer

• No compressed air required

What is EMFR?

Electromagnetic force restoration (EMFR) combines electrical and mechanical components. The design of EMFR weigh cells is based on a balance mechanism. It consists of a position indicator, a controller and an electro-magnetic drive (coil and permanent magnet). In its functionality, the Weigh Cell can be compared to a simple beam balance. If a weight is placed on one side of the beam, the opposite side of the weighing beam attempts to move out of the magnet’s magnetic field. The position indicator detects this deviation and the amount of current required for balancing the beam and ensuring that no position change can occur is transmitted through the coil. As the current is proportional to the weight and can be measured via a resistor, it can be converted into a digital signal which is used for further processing.

Our WeightCheq 0-250 is suited for all industries as your go to high accuracy check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Parts Description Material of Frame 304 Stainless steel Weighing range (g) 0 – 250 Best accuracy (g) ±0.01 Features

• Electromagnetic force restoration (EMFR) weigh cell

• Complete stainless steel/aluminum construction

• Heavy-duty frame structure

• Heavy-duty CNC machined foot pads

• High precision load cell

• Modular frame design

• Product accumulation drawer

• Food grade belts

• Anti-static Lexan safety guard

• Rejection system

• No changeover parts required

• Multi-color warning light with buzzer

• No compressed air requiredWhat is EMFR?

Electromagnetic force restoration (EMFR) combines electrical and mechanical components. The design of EMFR weigh cells is based on a balance mechanism. It consists of a position indicator, a controller and an electro-magnetic drive (coil and permanent magnet). In its functionality, the Weigh Cell can be compared to a simple beam balance. If a weight is placed on one side of the beam, the opposite side of the weighing beam attempts to move out of the magnet’s magnetic field. The position indicator detects this deviation and the amount of current required for balancing the beam and ensuring that no position change can occur is transmitted through the coil. As the current is proportional to the weight and can be measured via a resistor, it can be converted into a digital signal which is used for further processing.

- Ideal Markets

Our WeightCheq 0-250 is suited for all industries as your go to high accuracy check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

WeightCheQ 3-100

Automatic Check Weighing

The industry-leading WeightCheQ™ series of check weighers offers speed, accuracy and easy operation. These machines can be used to check the weight of a variety of packages including bags, bottles, cartons and cases and are easily integrated into existing packaging systems where automatic bagging, container filling, flow wrapping and case filling is performed.

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch• With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

| Parts | Description |

|---|---|

| Material of Frame | 304 Stainless steel |

| Weighing range (g) | 3 – 100 |

| Minimum scale (g) | 0.1 |

| Best accuracy (g) | ±0.2 |

| Max throughput (pcs/min) | 100 |

| Width of weighing belt (mm) | 220 |

| Length of weighing belt (mm) | 450 |

| Height of conveyor belt (mm) | 780-900 |

| Direction of throughput | From left to right when facing control panel |

| Alarm mode | Audible and visual |

| Reject device | Default: Air pusher Option: Flipper |

| Power | 240V 1 Phase |

| Working environments | Free of obvious vibration and air flow |

Our WeightCheq 3-100 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specification

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch• With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

Parts Description Material of Frame 304 Stainless steel Weighing range (g) 3 – 100 Minimum scale (g) 0.1 Best accuracy (g) ±0.2 Max throughput (pcs/min) 100 Width of weighing belt (mm) 220 Length of weighing belt (mm) 450 Height of conveyor belt (mm) 780-900 Direction of throughput From left to right when facing control panel Alarm mode Audible and visual Reject device Default: Air pusher

Option: FlipperPower 240V 1 Phase Working environments Free of obvious vibration and air flow - Ideal Markets

Our WeightCheq 3-100 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

WeightCheQ 10-4000

Automatic Check Weighing

The industry-leading WeightCheQ™ series of check weighers offers speed, accuracy and easy operation. These machines can be used to check the weight of a variety of packages including bags, bottles, cartons and cases and are easily integrated into existing packaging systems where automatic bagging, container filling, flow wrapping and case filling is performed.

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch

- With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

| Parts | Description |

|---|---|

| Material of Frame | 304 Stainless steel |

| Weighing range (g) | 10 – 4000 |

| Minimum scale (g) | 0.1 |

| Best accuracy (g) | ±1 |

| Max throughput (pcs/min) | 80 |

| Width of weighing belt (mm) | 300 |

| Length of weighing belt (mm) | 550 |

| Height of conveyor belt (mm) | 780-900 |

| Direction of throughput | From left to right when facing control panel |

| Alarm mode | Audible and visual |

| Reject device | Default: Air pusher Option: Flipper |

| Power | 240V 1 Phase |

| Working environments | Free of obvious vibration and air flow |

Our WeightCheq 10-4000 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specification

Features

- Strain gauge load cell with fast speed response

- Weighing parameter settings with intelligent self-learning function

- Dynamic weight tracking with automatic compensation, improve the stability

- With product presets, easy to edit and switch

- With weighing history query and USB export function

- 304 stainless steel frame, strong and durable

Parts Description Material of Frame 304 Stainless steel Weighing range (g) 10 – 4000 Minimum scale (g) 0.1 Best accuracy (g) ±1 Max throughput (pcs/min) 80 Width of weighing belt (mm) 300 Length of weighing belt (mm) 550 Height of conveyor belt (mm) 780-900 Direction of throughput From left to right when facing control panel Alarm mode Audible and visual Reject device Default: Air pusher

Option: FlipperPower 240V 1 Phase Working environments Free of obvious vibration and air flow - Ideal Markets

Our WeightCheq 10-4000 is suited for all industries as your go to check weighing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.