R2B 3600 SIMPLEX

HORIZONTAL FORM FILL AND SEAL MACHINE

Produce stunning pouches from roll stock

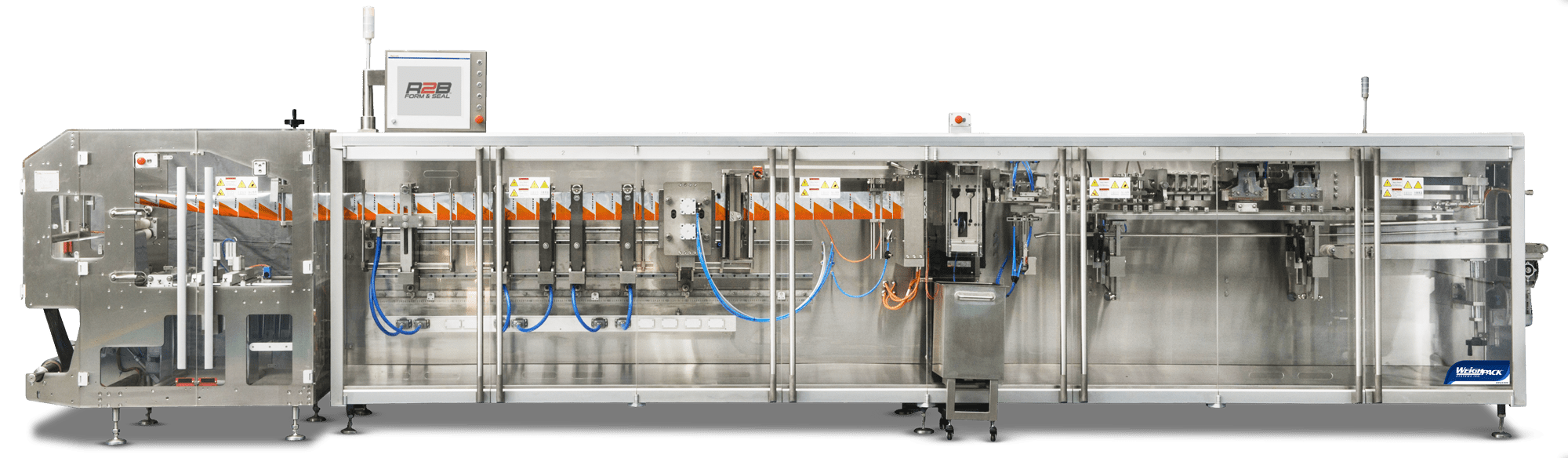

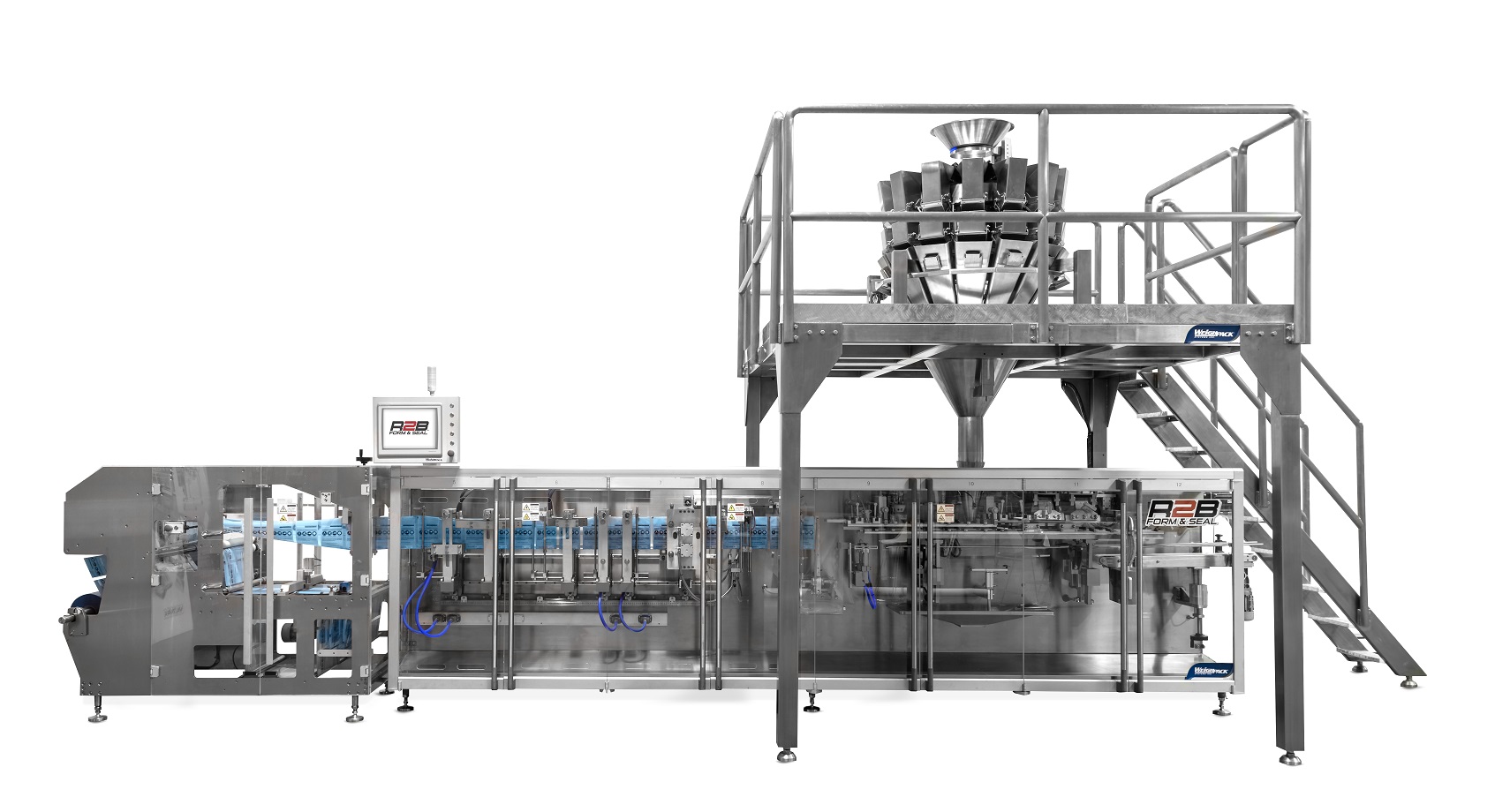

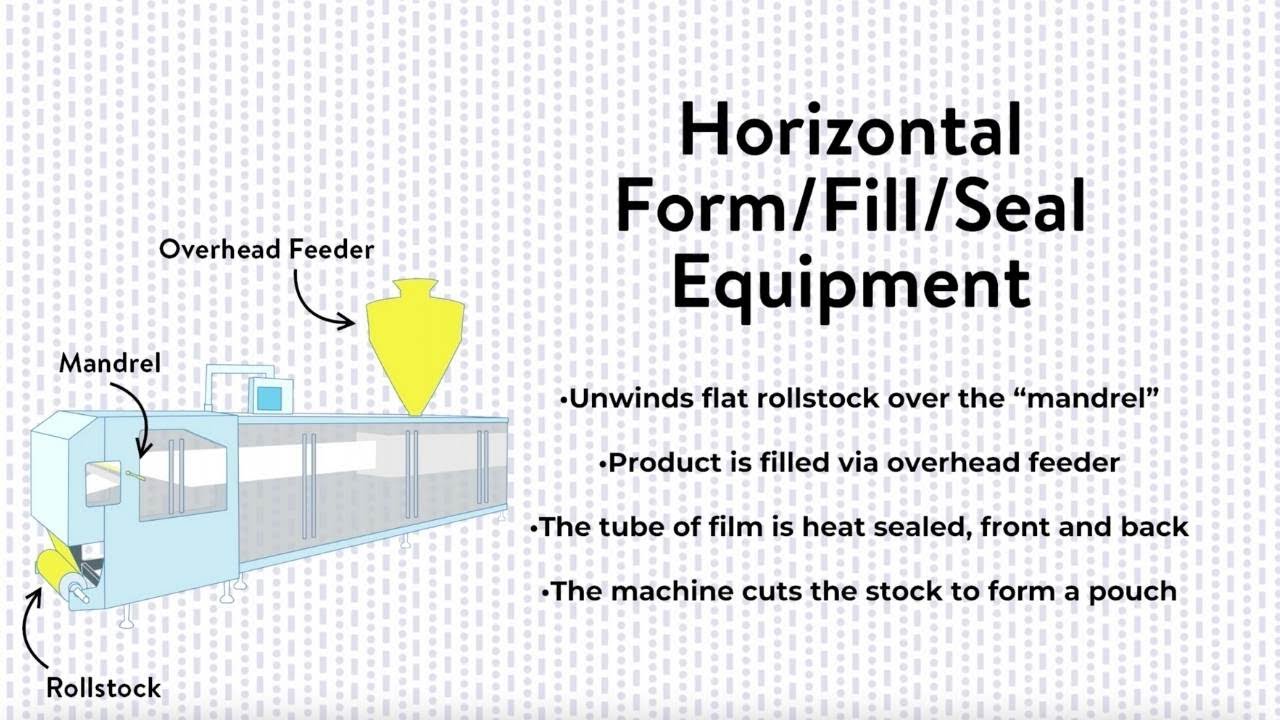

The high-performance R2B horizontal form fill and seal machine integrates the forming, filling and sealing process into one system.

This fully servo-driven machine can produce stand-up DOY pouches and both 3-sided seal and 4-sided seal pouches with zipper closures as well as shaped pouches requiring die cuts. It is also capable of inserting a corner rigid spout.

The R2B uses laminated roll stock film to create a large variety of pouch styles, thus eliminating the need for premade bags and reducing material cost dramatically; at times realizing savings of up to 30% over purchasing premade packaging.

Available options include gas flush, hole punch, middle capping device, shaped bag molding device, stand-up pouch former, tare notch, vacuum station, zipper applicator and rigid spout inserter.

Ideal applications include foods, pharmaceuticals, life sciences products, beverages, liquids and household care items.

Videos

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

- Ideal Markets

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

R2B 3600 SIMPLEX

HORIZONTAL FORM FILL AND SEAL MACHINE

Videos

Produce stunning pouches from roll stock

The high-performance R2B horizontal form fill and seal machine integrates the forming, filling and sealing process into one system.

This fully servo-driven machine can produce stand-up DOY pouches and both 3-sided seal and 4-sided seal pouches with zipper closures as well as shaped pouches requiring die cuts. It is also capable of inserting a corner rigid spout.

The R2B uses laminated roll stock film to create a large variety of pouch styles, thus eliminating the need for premade bags and reducing material cost dramatically; at times realizing savings of up to 30% over purchasing premade packaging.

Available options include gas flush, hole punch, middle capping device, shaped bag molding device, stand-up pouch former, tare notch, vacuum station, zipper applicator and rigid spout inserter.

Ideal applications include foods, pharmaceuticals, life sciences products, beverages, liquids and household care items.

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- AB PLC

- AB color touch screen

- Color touch screen

- Adjustable bag width and length

- Straight flow-through design

- Easy access drive mechanisms

- SMC & Festo sensors

- Festo valves

- Festo vacuum generator

- Integrated exit conveyor

- Encoder positioning logic

- Separate mounted film unwind with air actuated film shaft

- 304 Stainless steel sheet metal

- Heavy duty construction

- Easy access panels

- VFD variable speed control

UP TO 60 PER MINUTE / 200MM WIDE

*Rates subject to package style, type and size

- Ideal Markets

Our R2B 3600 is suited for all industries as your go to horizontal bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.